2025 Guide: How to Choose the Best 1 Ton Gantry Crane for Your Needs

In the fast-evolving world of material handling, choosing the right equipment is crucial for operational efficiency and safety. The 1 ton gantry crane, a versatile and robust solution for various lifting applications, has become increasingly popular across industries. According to a recent report by the Material Handling Industry of America (MHIA), the market for portable lifting solutions is projected to grow by 7% annually, driven by the increasing demand for flexible and efficient handling systems. As organizations strive to optimize their workflows, selecting the most suitable gantry crane has emerged as a pivotal decision.

Expert insights highlight the importance of making informed choices. John Smith, a renowned industry expert and author of the influential book "Cranes and Lifting Technology," emphasizes, “Investing in the right 1 ton gantry crane can profoundly impact your operational efficiency and safety metrics.” As businesses seek to enhance their productivity while maintaining employee safety, understanding the specific needs and capabilities of various gantry cranes becomes essential. This guide aims to provide an overview of the key factors to consider when selecting the best 1 ton gantry crane that aligns with your operational requirements, ensuring that you make a knowledgeable investment that meets your needs effectively.

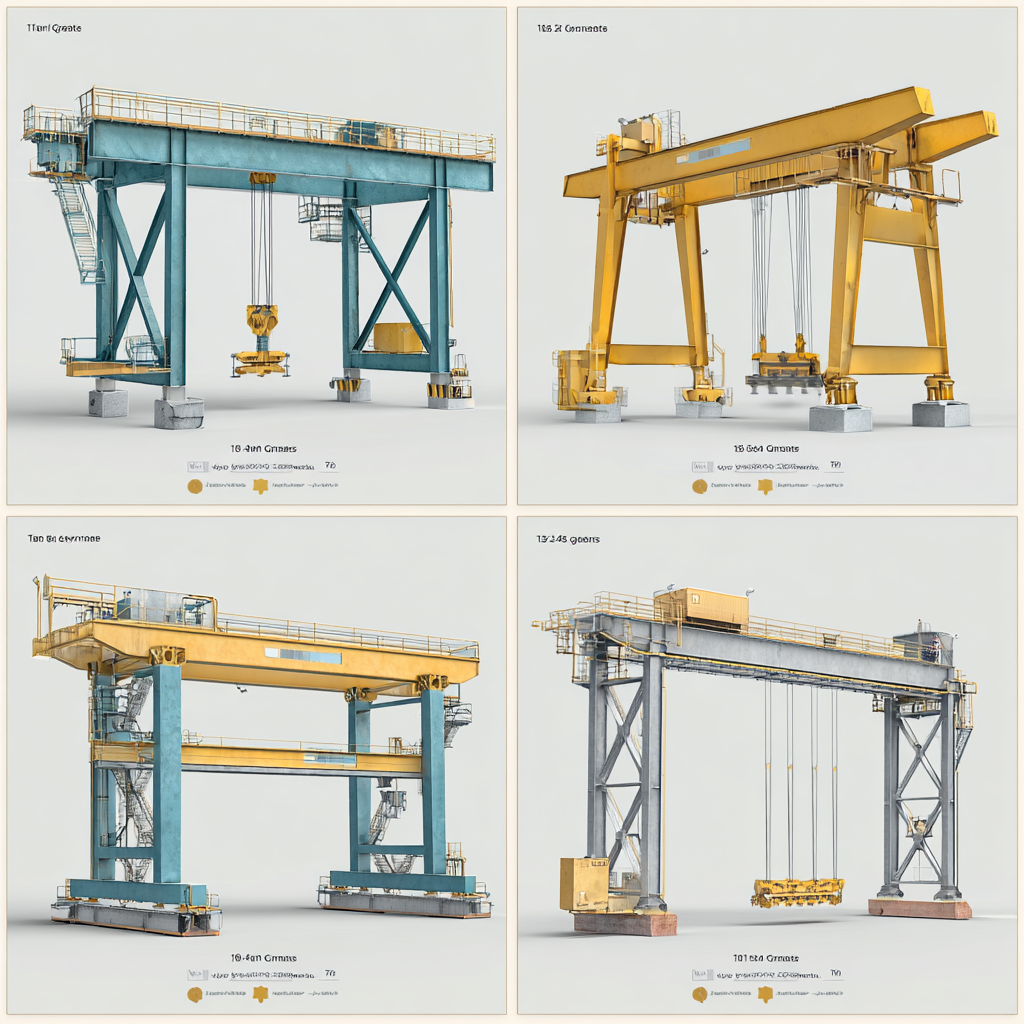

Understanding the Different Types of 1 Ton Gantry Cranes Available in 2025

When selecting a 1-ton gantry crane in 2025, it's crucial to understand the various types available to match your specific application needs. The most common types are adjustable height, fixed height, and mobile gantry cranes. According to the latest report by the Material Handling Industry of America (MHIA), the demand for adjustable gantry cranes has surged by 20% over the past two years due to their versatility in multi-functional work environments. These cranes offer the flexibility to accommodate different lifting height requirements, making them ideal for facilities that require frequent adjustments.

Moreover, fixed height gantry cranes are favored in settings where consistent lifting height is critical. They are recognized for their stability and heavy-duty construction, suitable for manufacturing plants. Industry data indicates that the market for fixed height gantry cranes has increased by over 15%, particularly in sectors like construction and automotive manufacturing, where reliability and strength are paramount. Mobile gantry cranes, on the other hand, are gaining traction in warehouses and smaller workspaces due to their ease of transport and setup, with sales having risen by 10% according to a report from The Association of Equipment Manufacturers (AEM). Understanding these distinctions will help you make an informed decision tailored to your operational needs.

2025 Guide: How to Choose the Best 1 Ton Gantry Crane for Your Needs

| Type of Gantry Crane | Weight Capacity | Span | Height Adjustment | Material | Mobility |

|---|---|---|---|---|---|

| Fixed Gantry Crane | 1 Ton | 3m | No | Steel | Stationary |

| Adjustable Gantry Crane | 1 Ton | 4m | Yes | Aluminum | Portable |

| Mobile Gantry Crane | 1 Ton | 5m | No | Steel | Wheeled |

| Cantilever Gantry Crane | 1 Ton | 4m | No | Steel | Stationary |

Key Factors to Consider When Selecting a 1 Ton Gantry Crane

When selecting the best 1 ton gantry crane for your needs, it’s essential to consider several key factors to ensure you make an informed decision. First, assess the lifting height and span of the crane. Understanding the specific dimensions of your workspace will help you choose a crane that can accommodate your materials while maximizing efficiency. Additionally, contemplate the terrain where the crane will operate—whether it's on a flat surface or uneven ground, as this will influence the stability and mobility of the equipment.

**Tip:** Before purchasing, always check the crane's load capacity and safety features. Look for models with safety certifications and overload protection systems to minimize risks during operation.

Another crucial aspect is the crane's mobility. If you require a crane that can easily move across different locations, investing in a portable gantry crane would be beneficial. On the other hand, if your lifting tasks are confined to a specific area, a fixed model might serve your needs better. Finally, consider the material and construction of the crane; aluminum models are lightweight and portable, while steel options offer enhanced durability for heavy-duty applications.

**Tip:** Review customer feedback and case studies to understand how the crane performs under real-world conditions, ensuring it aligns with your specific requirements.

Assessing Your Workspace: Dimensions and Weight Capacity Requirements

When selecting the best 1-ton gantry crane for your needs, it is crucial to assess your workspace's dimensions and weight capacity requirements. According to a 2023 report by the Material Handling Industry of America, the dimensions of your workspace can significantly influence the type of crane you should select, especially for industrial and manufacturing environments. Ensuring that the crane can fit comfortably within the available area without compromising maneuverability is essential. Most gantry cranes are available in various sizes, typically ranging from 8 to 24 feet in height and span, allowing for versatile setups that accommodate different operational needs.

Weight capacity is another critical factor that needs careful consideration. The National Crane Safety Association states that overloading is one of the leading causes of accidents in crane operations, emphasizing the importance of understanding not just the loads you expect to lift, but also factoring in any potential dynamic forces that may arise during lifting. It's recommended to choose a gantry crane with a weight capacity that exceeds your maximum expected load by at least 20%. This extra buffer will help enhance safety and ensure the longevity of the equipment, ultimately optimizing your operations.

Evaluating Material and Build Quality for Longevity and Durability

When selecting a 1 ton gantry crane, evaluating the material and build quality is paramount for ensuring longevity and durability. According to a report by the Material Handling Institute, equipment failures can lead to significant downtime and financial losses, with costs often exceeding $300,000 annually per business. Thus, understanding the materials used in crane construction—such as steel grades, weld quality, and coating systems—is crucial. High-quality steel not only enhances the crane's load-bearing capacity but also ensures resistance to wear and tear over time.

Additionally, the design and manufacturing processes play a vital role in the overall build quality. The Industrial Truck Association urges buyers to consider cranes that meet or exceed industry standards, such as those set by the American National Standards Institute (ANSI) and Occupational Safety and Health Administration (OSHA). By investing in a gantry crane with superior build quality—adhering to rigorous testing and quality control norms—companies can mitigate risks associated with equipment failure.

Research indicates that cranes built with comprehensive safety features and robust materials can extend operational lifespans significantly, achieving up to 20 years of effective service when properly maintained.

Cost Considerations: Budgeting for Your 1 Ton Gantry Crane Purchase in 2025

When budgeting for a 1 ton gantry crane in 2025, it's essential to consider several key factors that will impact the overall cost. First, the type of crane you choose can significantly influence the price. Fixed or adjustable height models may vary in cost due to their design complexity and adjustments capabilities. Additionally, the material used, whether steel or aluminum, will also affect the budget; steel cranes generally offer greater durability but come at a higher initial price.

Another crucial aspect to factor in is the potential additional costs associated with your purchase. Shipping fees, installation charges, and ongoing maintenance should all be accounted for in your budget. It's advisable to set aside a portion of your total budget for unforeseen expenses that may arise during installation or operation. Lastly, exploring financing options or leasing models can provide flexibility and help manage cash flow, making it easier to invest in the right gantry crane without stretching your resources too thin.

Related Posts

-

The Fascinating Evolution of Tower Cranes Revolutionizing Construction Technology

-

What is a Construction Crane? Understanding Types, Functions, and Uses in Modern Building Projects

-

What is a Central Crane and How Does it Improve Construction Efficiency

-

What is a Small Overhead Crane and How It Enhances Your Material Handling Efficiency?

-

What is a Truck Crane and How Does it Work

-

Maximizing Efficiency: How Grove Cranes Are Shaping the Future of Construction with 20% Increased Productivity