2025 Guide: How to Choose the Right Mobile Gantry Crane for Your Project

In the ever-evolving landscape of material handling, the choice of equipment plays a pivotal role in project success. As industries gear up for the transformative changes expected by 2025, it is crucial for professionals to understand the intricacies of selecting the right mobile gantry crane. According to a recent industry report by the Global Crane Manufacturers Association, the market for mobile gantry cranes is projected to grow at a CAGR of 5.3% from 2022 to 2027, reflecting an increasing reliance on flexible and efficient lifting solutions.

Expert insights emphasize the importance of tailored equipment choices. Dr. Emily Thornton, a leading authority in crane technology, notes, "Selecting the ideal mobile gantry crane is not just about load capacity; it's about matching the crane's capabilities with the specific demands of the project." Her words highlight the necessity for project managers to consider factors such as workspace dimensions, weight requirements, and mobility when making decisions. As the construction and manufacturing sectors continue to redefine their operational strategies, understanding these nuances will be vital for enhancing productivity and ensuring safety on job sites.

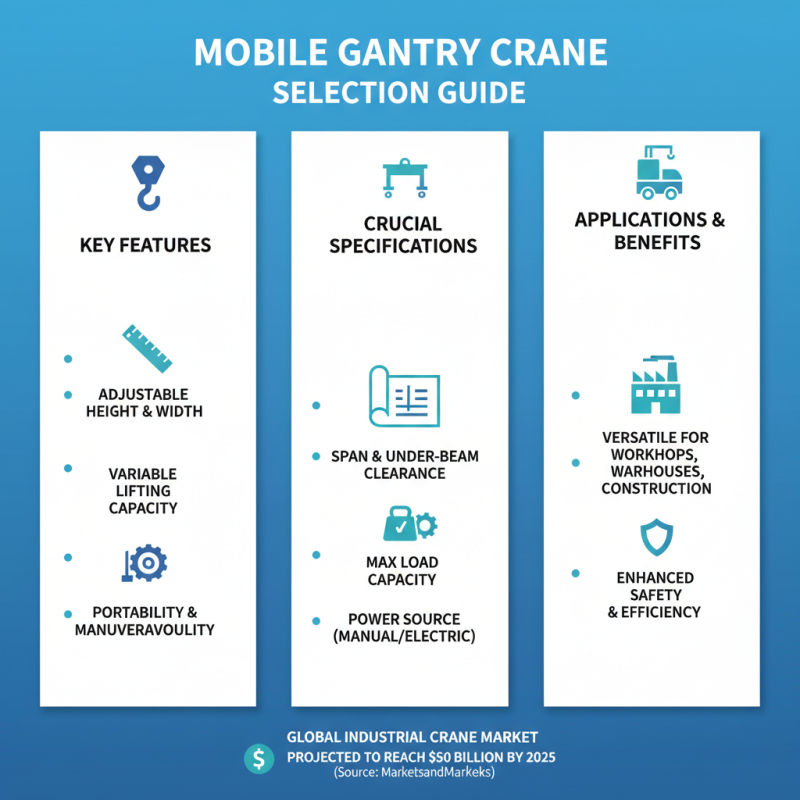

Understanding Mobile Gantry Cranes: Key Features and Specifications

When selecting a mobile gantry crane for your project, understanding the key features and specifications is crucial for ensuring optimal performance and safety. Mobile gantry cranes come in various designs, typically characterized by their adjustable height and width, making them versatile for different applications. According to a report by MarketsandMarkets, the global market for industrial cranes is projected to reach $50 billion by 2025, emphasizing the growing demand for adaptable lifting solutions in various industries.

One of the primary specifications to consider is the crane's load capacity, which can range widely from 500 kg to over 10,000 kg. This variation allows for targeted use in environments such as warehouses, construction sites, and manufacturing facilities. A 2022 analysis by ResearchAndMarkets indicates that the capacity and portability of these cranes directly impact operational efficiency and worker safety, underscoring the importance of assessing your specific lifting requirements before purchase. Additionally, features such as wheel type, height adjustability, and stability should align with the intended use to maximize operational effectiveness.

Another critical aspect is the crane's material composition, with options ranging from aluminum for lightweight applications to robust steel for heavy-duty tasks. The choice of material not only affects weight capacity but also influences durability and maintenance needs. The anticipated growth in the industrial sector underscores the necessity for crane users to invest in models that enhance safety and longevity, as reported in the latest industry forecast. Understanding these features and how they align with your project's demands ensures that you choose a mobile gantry crane that effectively meets your requirements.

Assessing Your Project Requirements for Mobile Gantry Crane Selection

When selecting the right mobile gantry crane for your project, the first step is to thoroughly assess your specific project requirements. Begin by evaluating the weight and dimensions of the loads you will be moving. Understanding the maximum load capacity needed will help you narrow down options and ensure that the crane can handle your operational demands safely and efficiently. Additionally, consider the dimensions of the work area; the crane must fit comfortably within the space while providing adequate clearance for lifting and maneuvering.

Next, consider the environmental conditions in which the crane will be used. Factors such as outdoor versus indoor use, ground stability, and potential obstructions can significantly influence your choice. For projects involving rough terrain or uneven surfaces, a crane designed with adjustable legs or larger wheels may be more appropriate. Furthermore, assess the frequency and duration of use. If the crane will be in constant operation, durability and ease of mobility become imperative. Taking these critical factors into account will guide you in selecting a mobile gantry crane that meets your project's unique requirements, ultimately enhancing efficiency and safety in your operations.

Evaluating the Safety Standards for Mobile Gantry Cranes

When selecting a mobile gantry crane for your project, safety standards should be your primary concern. These cranes must meet rigorous criteria to ensure the protection of operators and on-site personnel. Proper certification and compliance with local and international safety regulations are crucial steps in the evaluation process. It is essential to verify that the crane can support the intended loads while providing stability during operation, as instability can lead to accidents.

**Tips:** Always check for a comprehensive safety inspection report that details the crane's compliance with relevant standards. Evaluate the load capacity and operation area; the crane should have adequate features to prevent tipping or swaying while lifting heavy materials.

Additionally, consider the crane's design features, such as emergency stop functions, limit switches, and safety harness attachments. These elements contribute to a safer working environment and ensure that operators can respond quickly to any potential hazards. Regular maintenance should also be part of your safety protocol; a well-maintained crane significantly reduces the risk of malfunction and accidents during use.

**Tips:** Schedule routine inspections and maintenance checks to keep your mobile gantry crane in optimal condition. Ensure all operators are trained not only in using the equipment but also in recognizing safety concerns associated with its operation.

2025 Guide: Safety Standards Evaluation for Mobile Gantry Cranes

This chart illustrates the evaluation of various safety standards for mobile gantry cranes based on scores ranging from 0 to 100. High scores indicate better compliance with safety requirements.

Comparing Different Mobile Gantry Crane Models and Their Benefits

When selecting the right mobile gantry crane for your project, it's essential to compare different models and understand their unique benefits. Mobile gantry cranes come in various designs, each tailored to specific lifting capacities and operational environments. For instance, some models are equipped with adjustable height settings, making them adaptable to different workspaces. This feature can be crucial for projects with variable load requirements or limited headroom. Additionally, cranes with lightweight materials can enhance portability, allowing for easier maneuverability across job sites.

Another important factor to consider is the load capacity of each model. Some mobile gantry cranes are designed for light-duty tasks, while others can handle heavy loads exceeding several tons. Understanding your project's specific weight requirements ensures that you choose a crane capable of safely lifting and moving your materials. Furthermore, different models may offer varied wheel configurations and stability features, which can significantly impact their performance on uneven surfaces. Evaluating these aspects helps ensure that the mobile gantry crane operates efficiently and safely in your unique project environment.

Budgeting for Your Mobile Gantry Crane Purchase and Maintenance Costs

When budgeting for the purchase and maintenance of a mobile gantry crane, understanding the total cost of ownership is crucial. According to a recent industry report from Statista, the average price of a mobile gantry crane ranges from approximately $2,000 to $30,000 depending on specifications and lifting capacity. In addition to the initial purchase price, potential buyers should consider costs associated with maintenance, which can average around 10-15% of the equipment's value annually. This includes routine inspections, repairs, and necessary upgrades to ensure safety and compliance with industry standards.

**Tips:** When creating your budget, factor in not only the purchase price but also availability of spare parts and service support. Additionally, setting aside funds for operator training can enhance safety and operational efficiency, potentially reducing long-term costs.

Beyond the initial and maintenance costs, consider the financial implications of downtime caused by equipment failures. A report by Market Research Future indicates that improper maintenance can lead to a significant increase in downtime costs, which can exceed $50,000 for critical operations. Therefore, investing in quality equipment and regular maintenance can mitigate these expenses, ensuring your project stays on track and within budget.

**Tips:** It's advisable to perform a thorough cost-benefit analysis, comparing the potential costs of regular maintenance against the risks and financial impacts of equipment failure.

2025 Guide: How to Choose the Right Mobile Gantry Crane for Your Project - Budgeting for Your Mobile Gantry Crane Purchase and Maintenance Costs

| Specification | Value | Estimated Cost (USD) | Maintenance Frequency | Estimated Annual Maintenance Cost (USD) |

|---|---|---|---|---|

| Load Capacity | 1000 kg | $1,200 | Annual | $150 |

| Height Adjustment | 3 m to 5 m | $1,500 | Semi-Annual | $200 |

| Span Width | 2 m | $900 | Annual | $120 |

| Mobility Type | Wheeled | $1,800 | Quarterly | $250 |

| Material | Steel | $2,000 | Annual | $180 |

Related Posts

-

2025 Guide: How to Choose the Best 1 Ton Gantry Crane for Your Needs

-

What is a Construction Crane? Understanding Types, Functions, and Uses in Modern Building Projects

-

10 Essential Tips for Choosing the Right Hoist Crane for Your Project

-

Why Investing in Construction Cranes Boosts Project Efficiency and Reduces Costs

-

2025 Top Mobile Crane Innovations: What You Need to Know

-

What is a Small Overhead Crane and How It Enhances Your Material Handling Efficiency?