2025 Guide: How to Choose the Right Small Overhead Crane for Your Needs

In the rapidly evolving industrial landscape, selecting the appropriate equipment for your operations is crucial. The small overhead crane has emerged as a versatile solution for various lifting needs, particularly in confined spaces where larger cranes cannot operate. As John Smith, a seasoned expert in material handling solutions, aptly puts it, “Choosing the right small overhead crane can not only enhance productivity but also ensure safety and efficiency in your workspace.” This statement captures the essence of why understanding the different factors that influence your choice is essential.

When considering a small overhead crane, several elements come into play, including load capacity, span, and environment. Each of these factors contributes significantly to how well the crane will perform its intended tasks. Beyond technical specifications, the decision also hinges on understanding your unique operational requirements. As we delve into this guide, we'll explore the critical considerations and provide insights to help you make an informed choice.

In 2025, the demand for small overhead cranes is expected to rise, driven by advancements in technology and a growing emphasis on optimized workflows. This guide aims to equip you with the knowledge necessary to navigate the complexities of selecting the perfect crane for your needs, ensuring that you can make a selection that drives both safety and efficiency.

Understanding Small Overhead Cranes: Types and Applications

Small overhead cranes are essential tools in various industries, effectively lifting and moving loads in confined spaces. They come in several types, including bridge cranes, gantry cranes, and jib cranes, each designed for specific applications. According to industry reports from the Occupational Safety and Health Administration (OSHA), more than 200,000 workplaces utilize overhead cranes, emphasizing their critical role in enhancing productivity and safety in manufacturing, warehousing, and construction environments.

Bridge cranes are commonly used in large facilities where space optimization is key. These cranes can span large areas and offer a high lifting capacity, making them ideal for heavy-duty tasks. On the other hand, gantry cranes serve well in outdoor applications, allowing flexibility in operations without requiring permanent installation. Meanwhile, jib cranes are preferred for limited workspace, delivering precision in lifting loads in tight corners. In fact, a report by the Material Handling Industry of America (MHIA) suggests that installations of small overhead cranes have increased by 15% over the past five years, underscoring their growing importance in modern industry.

Understanding the specific characteristics and applications of each crane type can significantly influence purchasing decisions. Factors such as load capacity, lift height, and the facility layout should be evaluated to ensure that the selected crane meets operational needs while adhering to safety regulations. With the rising demand for efficient lifting solutions, small overhead cranes continue to revolutionize material handling across various sectors, reflecting advancements in technology and engineering.

Key Factors to Consider When Selecting a Small Overhead Crane

When selecting a small overhead crane, several key factors must be taken into account to ensure it meets your specific operational needs. One of the primary considerations is the lifting capacity. According to industry data, the average lifting capacity for small overhead cranes ranges from 1 to 10 tons, but it's essential to assess the maximum load you plan to handle, including safety margins. An appropriate lifting capacity will not only maximize efficiency but also minimize the risk of accidents and equipment failure.

Another critical factor is the span of the crane, which refers to the distance between supports. A report from the American Society of Mechanical Engineers highlights that spans typically vary based on application needs but can extend up to 20 feet for smaller units. A well-planned span measurement enables optimal usage of floor space while ensuring that the overhead crane can cover the necessary areas effectively. Additionally, the type of control system—manual, semi-automatic, or fully automatic—also plays a pivotal role in user experience and safety. Research indicates that cranes with advanced control systems enhance productivity while reducing operator fatigue, making it essential to choose a system that aligns with your operational demands and workforce capabilities.

2025 Guide: Key Factors in Choosing a Small Overhead Crane

This chart illustrates the importance rating (on a scale of 1 to 10) of various factors to consider when selecting a small overhead crane in 2025. These include load capacity, span length, lift height, power source, and control type, highlighting their influence on your purchasing decision.

Assessing Weight Capacity and Lifting Height Requirements

When selecting a small overhead crane, understanding weight capacity and lifting height requirements is essential to ensure optimal performance for your specific applications. First, consider the weight of the materials you will be lifting. This involves not only the maximum load but also any potential variations in weight due to packaging or additional components. Evaluating the total weight and incorporating safety margins will help you choose a crane that meets your needs, preventing the risk of overloading and extending the equipment's lifespan.

Lifting height is another critical factor influencing your choice of crane. Measure the vertical space available in your operation and determine the maximum lift required for your tasks. Ensure that the overhead crane can handle these heights effectively while maintaining stability and safety. Additionally, consider any obstacles that might limit lifting capabilities, such as beams or ductwork. By understanding both weight capacity and lifting height requirements, you can make informed decisions that enhance your workflow efficiency and ensure safe operations.

Evaluating Your Workspace: Dimensions and Obstructions

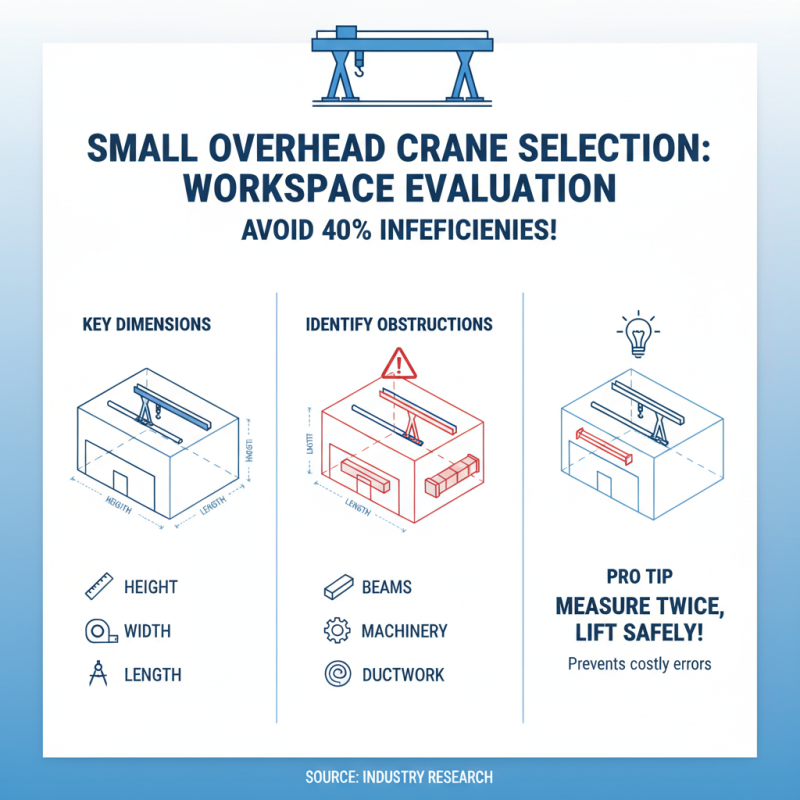

When selecting a small overhead crane, one of the most crucial steps involves evaluating your workspace, particularly its dimensions and potential obstructions. Research from industry publications indicates that nearly 40% of crane-related inefficiencies stem from improper spatial assessments. To avoid these pitfalls, it is vital to measure not only the height, width, and length of your workspace but also to identify any fixed or movable obstructions such as beams, machinery, or ductwork that could interfere with crane operation.

In addition to physical dimensions, the weight capacity and movement path of the crane must be assessed in relation to the layout of the workspace. A report by the Material Handling Industry (MHI) highlights that overly confined spaces can limit the effective use of a crane, leading to potential safety hazards or operational delays. For example, operators should account for the swing radius and clearance needed for the crane's components, which can vary considerably based on design. By meticulously analyzing these factors, businesses can not only enhance efficiency but also ensure a safer working environment for their employees, ultimately leading to reduced downtime and improved productivity.

Maintenance and Safety Considerations for Overhead Cranes

When selecting a small overhead crane, one crucial aspect that should never be overlooked is maintenance and safety. Regular maintenance ensures that the crane operates at optimal efficiency and significantly reduces the risk of accidents. Routine inspections, including checks on the hoist, cables, and control systems, should be conducted to identify wear and tear before they lead to operational failures. Keeping an accurate maintenance log is essential for tracking service history and identifying patterns that may indicate underlying issues that need to be addressed.

Safety considerations are equally vital when operating overhead cranes. Comprehensive training programs for all personnel involved in crane operations are necessary to ensure they understand the specific hazards associated with crane use and how to mitigate them. Additionally, implementing safety protocols, such as proper load-handling techniques and the use of personal protective equipment, can further minimize risks. It is essential to conduct regular safety audits and drills to keep the adherence to safety measures sharp and reinforce a culture of safety within the workplace.

Related Posts

-

What is a Small Overhead Crane and How It Enhances Your Material Handling Efficiency?

-

What is an Overhead Gantry Crane? Benefits, Uses, and Key Features Explained

-

What is a Construction Crane? Understanding Types, Functions, and Uses in Modern Building Projects

-

Top 5 Benefits of Using a 2 Ton Gantry Crane for Your Projects

-

The Ultimate Guide to Choosing the Best Service Crane in 2025

-

How to Choose the Right Industrial Crane for Your Construction Projects