Top 5 Best 2 Ton Crane Options for Heavy Lifting Tasks?

When it comes to heavy lifting tasks, the right equipment is essential. A 2 ton crane can make all the difference in efficiency and safety. John Smith, a leading expert in crane technology, emphasizes this point: “Choosing the right 2 ton crane is crucial for getting the job done right.”

This lightweight yet powerful option stands out in various industrial settings. It can elevate materials with precision. The design of a 2 ton crane allows for mobility and ease of use. Yet, not all cranes are created equal. Each model presents unique features and capabilities that fit specific needs.

Understanding the details of these options is important. It involves assessing load capacities, reach, and ease of setup. Some models excel in portability; others prioritize stability. It can be challenging to navigate these choices. Choosing the best 2 ton crane may require careful evaluation. However, making an informed decision can lead to significant operational improvements.

Overview of 2 Ton Cranes and Their Applications

2 ton cranes are versatile tools used across various industries. They provide essential lifting power for heavy equipment, materials, and even vehicles. In construction, these cranes help move steel beams and concrete blocks with ease. They are also employed in manufacturing for transporting heavy machinery within factories. Their capabilities make them invaluable on job sites.

However, the use of a 2 ton crane is not without challenges. Proper training is crucial to avoid accidents. Operators must understand load limits and stability. Without this knowledge, lifting heavy items can lead to dangerous situations. It's vital to regularly inspect the equipment for wear and tear. Neglecting maintenance can result in equipment failure.

While they offer many benefits, 2 ton cranes require careful consideration. Each task must be assessed to determine if a crane is the right choice. Assessing site conditions, load types, and distances is necessary. This reflection can help in making more informed decisions. Balancing efficiency and safety is key to successfully using these cranes for heavy lifting tasks.

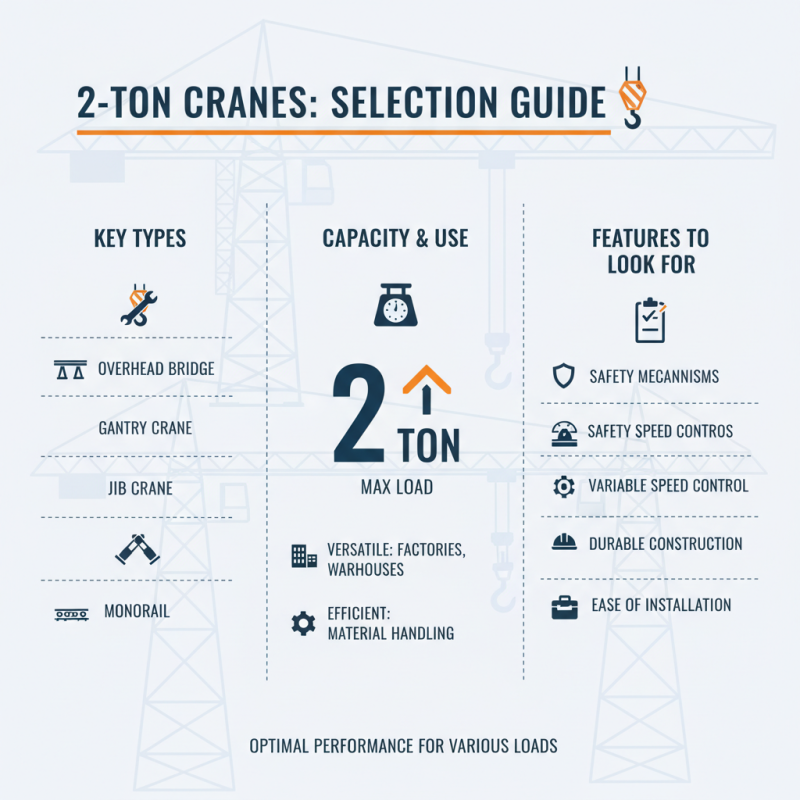

Key Features to Consider When Choosing a 2 Ton Crane

When considering a 2 ton crane for heavy lifting tasks, specific features are vital. Weight capacity is the most important. A crane that precisely meets your lifting needs improves safety. A crane that cannot handle the load could lead to accidents. Size and footprint also matter. Ensure it fits in your workspace without obstructing other activities.

Operational ease is crucial. Look for features like adjustable heights and ease of assembly. A user-friendly design saves time and energy. Think about mobility as well. Some cranes have wheels for easy relocation, while others are stationary. Each design serves different lifting environments.

Safety features should never be overlooked. Look for cranes with robust safety mechanisms, such as emergency stop buttons. Stability is also critical. A crane that tips over can cause serious injuries. Regular maintenance is essential, too. Ignoring this can lead to malfunctions at crucial moments.

Top 5 Recommended 2 Ton Cranes for Heavy Lifting

When it comes to heavy lifting tasks, choosing the right 2-ton crane is crucial. These cranes are versatile and can handle various loads efficiently. The demand for reliable options has led to the emergence of several models that cater to different needs. Understanding the specifications and features is essential to ensure optimal performance.

Always consider the weight capacity. Not all 2-ton cranes can lift the same effectively. Some may provide a margin of safety, while others might underperform. Pay attention to the lifting height. A crane that cannot reach the necessary height may lead to issues during your projects. Stability is another key factor. If a crane isn't stable, it might fail under load, posing safety risks.

Tips: Maintenance is vital. Regular checks can prevent accidents and ensure the crane operates smoothly. Training is also important. Operators must be skilled to handle cranes properly. Inefficient handling can lead to mistakes, so investing time in training is worthwhile. Lastly, while some cranes may boast advanced features, it's essential to reflect on your actual needs to avoid overspending on unnecessary functionalities.

Comparison of Performance and Durability Among Best Options

When selecting a 2-ton crane, performance and durability are crucial factors. According to industry reports, lifting capacity directly ties to a crane's design quality. Cranes that use high-strength steel tend to have better load-bearing capabilities. This material choice can reduce wear and increase longevity, especially in heavy lifting tasks.

Another report highlighted that many cranes in the market struggle with stability. A crane's base design affects its performance, particularly under maximum load. Units with broader outriggers often outperform those with narrower ones during heavy lifting. The difference can be significant, with stability ratings varying up to 30% among different models. Operators need to consider these factors carefully.

Durability is often a reflection of how well a crane can handle repeated use. Poorly manufactured cranes may show signs of wear within months. In contrast, high-quality cranes can last over five years with regular maintenance. Investing in a crane that combines both performance and durability leads to better long-term costs. Despite the price, the value becomes evident over time.

Top 5 Best 2 Ton Crane Options for Heavy Lifting Tasks

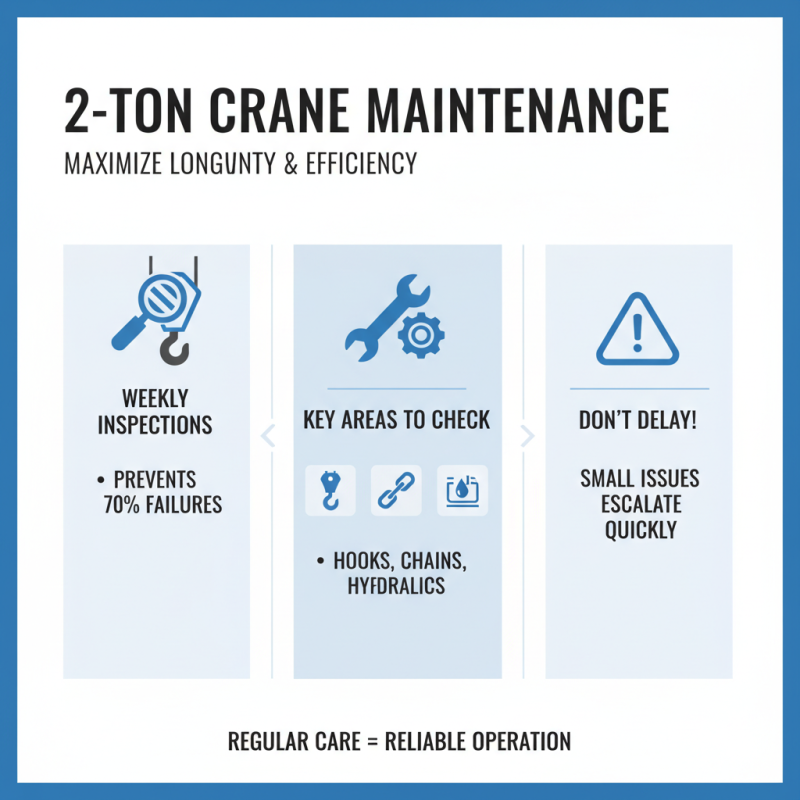

Maintenance Tips for Maximizing Crane Longevity and Efficiency

Proper maintenance is key to maximizing the longevity and efficiency of 2-ton cranes. Research indicates that regular inspections can prevent up to 70% of operational failures. Cranes should be examined weekly for wear and tear. Key areas include hooks, chains, and the hydraulic system. Minor issues can escalate quickly if not addressed.

Lubrication is critical for crane components to operate smoothly. A report from the Crane Safety Institute suggests that maintaining proper lubrication can extend the lifespan of a crane by 30%. However, many operators overlook this simple task. Ensuring that all parts are adequately lubricated reduces friction and wear, leading to more efficient operations.

Operator training is another vital factor often underestimated. A study showed that around 90% of crane accidents are due to operator error. Regular training sessions can help personnel understand equipment limitations and best practices. Inadequate training can lead to costly mistakes and reduced productivity. Each crane operation should emphasize safety first, and efficiency will follow.

Related Posts

-

Top 5 Benefits of Using a 2 Ton Gantry Crane for Your Projects

-

Top 10 Overhead Gantry Crane Benefits and Applications You Should Know

-

2025 Guide: How to Choose the Best 1 Ton Gantry Crane for Your Needs

-

2025 Top Trends in Hoist and Crane Technology for Industrial Applications

-

Why Investing in Construction Cranes Boosts Project Efficiency and Reduces Costs

-

What is an Industrial Crane? Types, Uses, and Key Considerations Explained