How to Choose the Right Industrial Crane for Your Construction Projects

Selecting the right industrial crane for construction projects is a critical decision that can significantly impact efficiency and safety on the job site. According to industry research conducted by the Freedonia Group, the global crane market is projected to reach $23 billion by 2025, driven by increasing infrastructure investments and a growing demand for complex lifting tasks. Given the variety of available cranes—including tower cranes, mobile cranes, and overhead cranes—understanding the specific requirements of your project is essential for optimizing performance and minimizing costs.

Moreover, the Occupational Safety and Health Administration (OSHA) statistics highlight that improper crane selection can lead to severe accidents and costly downtime, emphasizing the importance of choosing the right equipment. For instance, a report by the National Institute for Occupational Safety and Health (NIOSH) indicates that crane-related incidents account for a significant percentage of construction fatalities. Therefore, construction managers and project planners must meticulously evaluate load specifications, site conditions, and operational requirements to ensure they select an industrial crane suited to their specific needs. By doing so, they not only enhance productivity but also prioritize the safety and well-being of their workforce.

Understanding Different Types of Industrial Cranes Available for Construction

When selecting the right industrial crane for construction projects, it is essential to understand the different types of cranes available and their specific capabilities.

Tower cranes, for instance, are commonly used in high-rise construction due to their ability to reach great heights and lift heavy loads. According to the International Journal of Industrial Engineering, tower cranes can typically lift between 10 to 20 tons, making them vital for projects that require significant vertical movement of materials.

Another significant category is mobile cranes, which offer flexibility and ease of mobility on construction sites. These cranes can be transported easily between locations and can operate in varied terrain. The Global Crane Market Report indicates that mobile cranes account for approximately 35% of the market share due to their versatility and wide application in both construction and industrial settings. They are particularly effective for projects that require frequent relocation and quick setup times.

Lastly, overhead cranes, or bridge cranes, are indispensable in manufacturing and storage environments. They utilize a fixed track system to transport materials across a defined area efficiently. The Occupational Safety and Health Administration (OSHA) reports that the use of overhead cranes has increased by over 20% in the last decade, largely due to advancements in technology that enhance safety and operational efficiency. Understanding these types, along with their respective specifications and applications, is crucial for making an informed decision that aligns with the specific demands of a construction project.

Evaluating Load Capacity and Reach Requirements for Your Project

When selecting the right industrial crane for your construction project, evaluating load capacity and reach requirements is critical. Load capacity refers to the maximum weight the crane can safely lift, whereas reach indicates how far the crane can extend to place materials. Understanding these two factors will help you determine the best crane type for your specific needs, ensuring efficiency and safety throughout the project.

Tips: Always calculate the total weight of the materials you plan to lift, including any additional attachments. It's crucial to factor in both static loads and dynamic loads, which can be influenced by wind, movement, or other variables. Be conservative in your estimates; opting for a crane with a higher load capacity than you expect to need may save you from unwanted complications.

Moreover, consider the site's layout and obstacles when assessing reach requirements. The crane's boom length and type should provide ample coverage for your operation while being mindful of surrounding structures. Take into account not just the maximum reach, but also the working radius at various boom angles to optimize your crane usage.

Tips: Conduct a thorough site assessment to identify potential obstructions and plan the crane's positioning accordingly. Engaging with your team in this evaluation process can lead to improved safety measures and operational efficiency.

Load Capacity and Reach Requirements for Industrial Cranes

This chart presents the load capacity and reach requirements for different types of industrial cranes commonly used in construction projects. The data illustrates how various cranes are suited for differing project needs based on their load capacity (in tons) and reach (in meters).

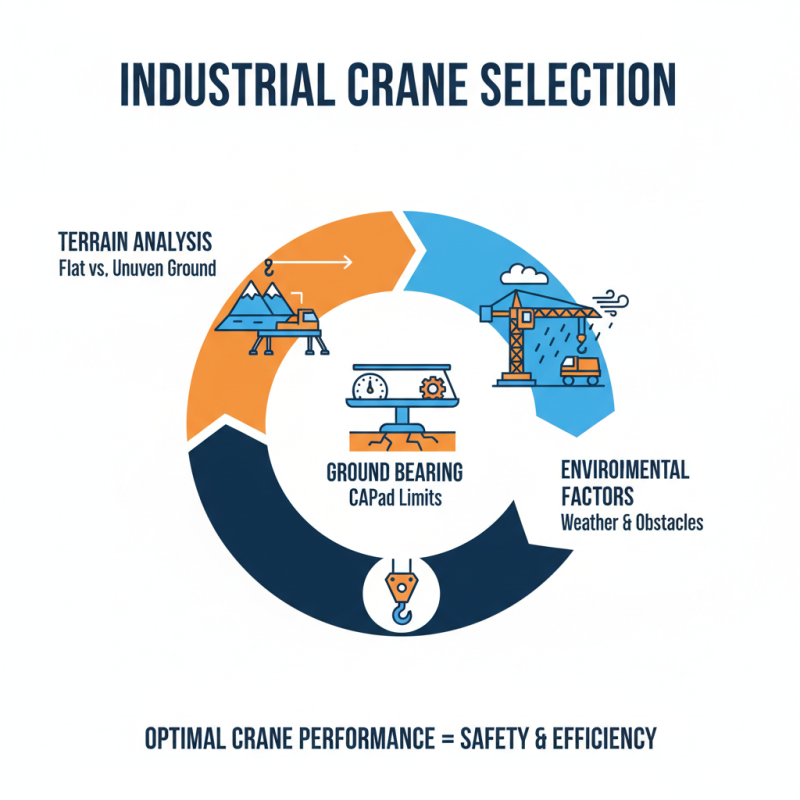

Assessing Site Conditions and Environment for Crane Selection

When selecting the right industrial crane for construction projects, it is crucial to assess the site conditions and environmental factors that can significantly impact crane performance. Analyzing the terrain is the first step; flat, stable ground may allow for a different type of crane compared to uneven or soft soil, which might require a more specialized machine with additional support mechanisms. Understanding the weight limits of the ground surface is also vital, as cranes can exert substantial loads that may lead to ground failure if not appropriately managed.

Additionally, the surrounding environment plays a critical role in crane selection. Factors such as overhead obstacles, access routes, and space constraints must be carefully evaluated. In urban areas, cranes may need to navigate tight spaces and work around buildings, requiring models with a smaller footprint or greater maneuverability. Weather conditions also influence crane operation; high winds, rain, and extreme temperatures can affect stability and safety, warranting the selection of cranes equipped with specific features to handle these challenges. By conducting a thorough assessment of both site conditions and environmental factors, construction managers can make informed decisions that enhance efficiency and safety during lifting operations.

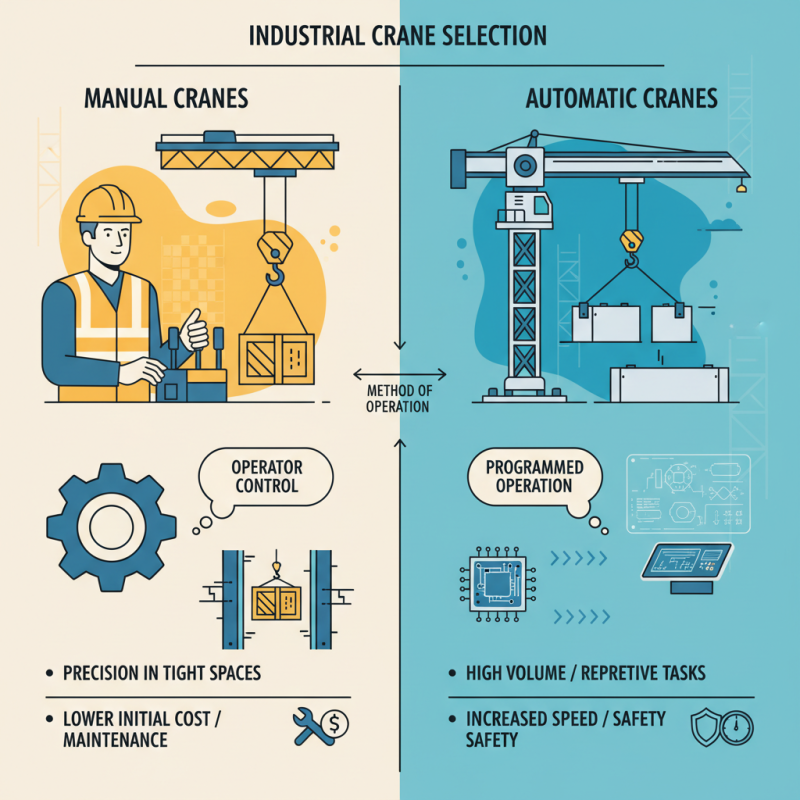

Comparing Crane Features: Manual vs. Automatic Operation

When selecting an industrial crane for construction projects, one key factor to consider is the method of operation—whether to go for manual or automatic cranes. Manual cranes require operators to physically control the lifting and moving of loads, providing a high level of precision in smaller-scale operations. This direct control can be particularly advantageous in tight spaces or when handling delicate materials, where an operator’s judgment and skill come into play. Additionally, manual cranes often have lower upfront costs and maintenance requirements, making them suitable for businesses with budget constraints.

On the other hand, automatic cranes offer several benefits, especially for larger construction sites. With automated systems, operators can accomplish tasks from a safer distance, reducing the risk of injury associated with manual operation. These cranes can handle heavy loads and complex movements with greater efficiency, improving overall productivity. Furthermore, automation can streamline operations by minimizing downtime typically associated with human error. Each type of operation has its own set of advantages, and the choice ultimately depends on the specific requirements of the project, site conditions, and available workforce capabilities.

Budgeting for Crane Rental or Purchase: Cost Considerations

When it comes to budgeting for crane rental or purchase, the first step is to determine the specific needs of your construction project. Factors such as the project's size, duration, and the type of materials to be handled play a pivotal role in the overall cost. Rental prices can vary significantly based on the crane's capacity and the length of time it will be needed. For temporary projects, renting might be the most cost-effective choice, as it allows for flexibility without the burdens of ownership. However, for long-term projects, purchasing a crane could lead to substantial savings in the long run.

In addition to the direct costs of rental or purchase, it’s crucial to consider ancillary expenses that may arise. These can include transportation fees, maintenance costs, insurance, and operator training. Moreover, downtime caused by equipment failure should also be factored into your budget, as it can lead to delays and increased labor costs. By comprehensively assessing these expenses and aligning them with your construction schedule, you can create a more accurate financial plan that supports the successful execution of your project.

In addition to the direct costs of rental or purchase, it’s crucial to consider ancillary expenses that may arise. These can include transportation fees, maintenance costs, insurance, and operator training. Moreover, downtime caused by equipment failure should also be factored into your budget, as it can lead to delays and increased labor costs. By comprehensively assessing these expenses and aligning them with your construction schedule, you can create a more accurate financial plan that supports the successful execution of your project.

Related Posts

-

Maximizing Efficiency: How Grove Cranes Are Shaping the Future of Construction with 20% Increased Productivity

-

What is a Central Crane and How Does it Improve Construction Efficiency

-

10 Essential Tips for Choosing the Right Hoist Crane for Your Project

-

What is a Small Overhead Crane and How It Enhances Your Material Handling Efficiency?

-

What is a Construction Crane? Understanding Types, Functions, and Uses in Modern Building Projects

-

What is an Overhead Gantry Crane? Benefits, Uses, and Key Features Explained