How to Choose the Right Construction Crane for Your Project?

Choosing the right construction crane for your project is crucial. A suitable crane can make a significant difference in productivity and safety. There are various types of construction cranes, and each serves specific needs.

When selecting a crane, consider the project size and site conditions. Will you need a tower crane for tall buildings or a mobile crane for flexibility? Each option has distinct advantages. A heavier load capacity is not always necessary. Assessing the environment, like limited space or overhead obstacles, can also influence your choice.

It is easy to overlook important details during the selection process. Sometimes, contractors might prioritize cost over efficiency, leading to potential issues. Reflecting on these choices can prevent setbacks down the line. Remember, the ideal construction crane matches both your project requirements and site challenges effectively.

Types of Cranes Commonly Used in Construction Projects

When choosing a construction crane, it's important to understand the different types available. Each crane serves a particular purpose.

Mobile cranes are versatile and can be moved easily between sites. They are often used for lifting heavy materials.

Tower cranes, on the other hand, provide height and stability. You'll see them in large construction projects like skyscrapers.

Tips: Ensure you assess site conditions before selecting a crane. The ground surface and obstacles may influence your choice. Don’t overlook safety features. A crane with proper safety measures is vital for worker protection.

Other common cranes include loader cranes and overhead cranes. Loader cranes are compact and mounted on vehicles. They excel in tight spaces where larger cranes cannot operate. Overhead cranes are fixed and commonly found in factories. They have great lifting capacity and can move materials effortlessly.

Tips: Always consult with experienced operators and engineers. Their insights can refine your crane selection. Consider the load capacity carefully. Underestimating it can lead to severe accidents and costly downtime.

Key Factors to Consider When Selecting a Construction Crane

Choosing the right construction crane involves several key factors. Understanding the project’s needs is crucial. The load capacity is one of the primary considerations. A crane that can’t handle the weight won’t get the job done. It’s also important to check the reach. Cranes come in various models, and some may not extend far enough.

You should evaluate the site conditions next. Is the ground stable or uneven? This affects the crane's setup and stability. Are there overhead obstacles? This can limit crane movement and flexibility. Safety is paramount. A crane that isn't suited for the environment may create hazards.

Another aspect is the cost. Budgeting for a crane can be tricky. Low-cost options may lead to unexpected challenges. Maintenance and operational costs must also be factored in. Often, overlooked equipment features can complicate operations. It’s wise to consult with experienced professionals. They can provide insights that save time and money. Knowing these details will prevent mistakes in your project choice.

How to Choose the Right Construction Crane for Your Project? - Key Factors to Consider When Selecting a Construction Crane

| Factor | Description | Importance |

|---|---|---|

| Load Capacity | The maximum weight the crane can lift. | High |

| Mast Height | The height of the crane's main structure affects its reach. | Medium |

| Mobility | Whether the crane is fixed or mobile impacts site logistics. | High |

| Site Conditions | The terrain and space availability can dictate crane choice. | High |

| Operating Radius | The distance a crane can lift loads horizontally. | Medium |

| Cost | The total budget available for crane rental or purchase. | High |

| Regulatory Compliance | Ensure the crane meets local safety standards. | Critical |

Assessing Project Requirements and Site Conditions for Crane Use

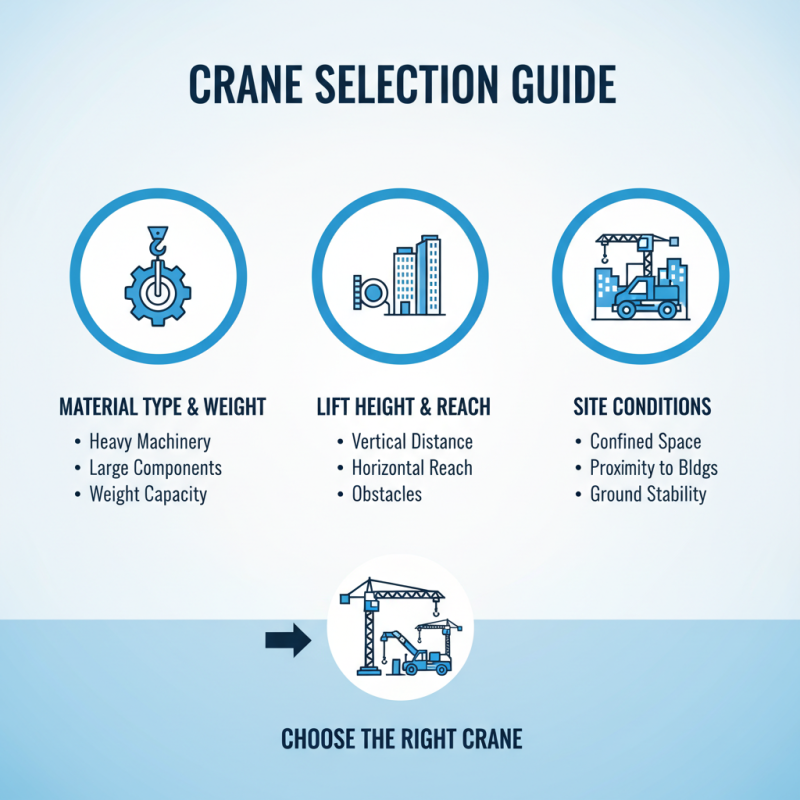

When selecting a crane, it's crucial to assess project requirements and site conditions thoroughly. The type of materials you'll lift plays a vital role in crane choice. Heavy machinery or large components may need a stronger crane. Also, consider the height from which you’ll lift. If you're working in a cramped space or near buildings, a compact crane may be necessary.

Site conditions can significantly influence crane operation. The ground must be stable. Soil type matters too. Soft ground could require additional support. Weather conditions should also be assessed before deciding. Wind can affect lifting operations and safety. Ensure your crane is suitable for the local environment.

Local regulations should not be overlooked. Understanding safety guidelines is critical. Communication with the team is essential, as everyone must be on the same page. Sometimes, it might feel overwhelming. Balancing requirements can lead to second-guessing your decision. However, careful contemplation can guide a more suitable choice. Proper planning is essential to make an informed decision.

Evaluating Load Capacity and Reach for Different Crane Types

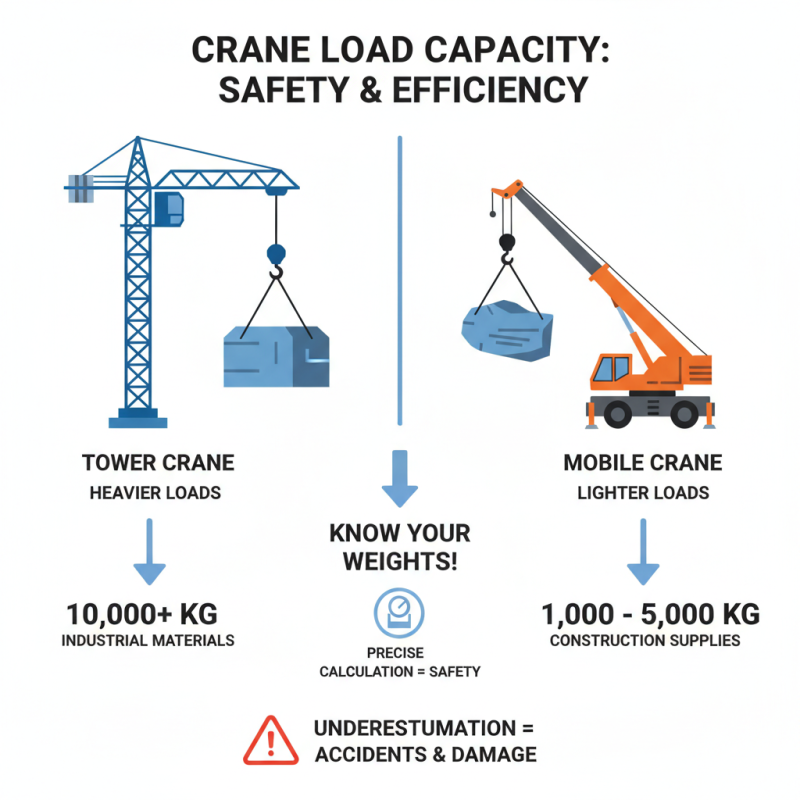

When selecting a crane, understanding load capacity is crucial. Different cranes have varying limits on how much weight they can lift. For example, a tower crane can typically handle heavier loads than a mobile crane. Knowing the precise weight of your materials ensures safety and efficiency. It's worth noting that underestimating the load can lead to accidents.

Reach is another vital factor. Crane reach determines how far the crane can lift and move materials. For instance, if your project site is confined, a crane with a shorter reach might suffice. However, if you are spanning a wide area, a crane with extended reach is essential. Considering the site’s layout is important. Tight spaces can complicate operations, and a reach that is too short may hinder progress.

Lastly, balancing load capacity and reach can be challenging. Often, a crane that offers a great load capacity may not have the best reach. This can lead to re-evaluations of plans and logistics. Always assess the project needs carefully. Sometimes a combination of crane types or services is necessary to meet specific demands effectively.

Safety Regulations and Certifications for Construction Cranes

When selecting a construction crane, safety regulations are paramount. According to a report by the Occupational Safety and Health Administration (OSHA), improper crane operation is a leading cause of construction site accidents. Each crane must comply with local safety standards. Ensure operators have the right certifications and training. Regular inspections are not just recommended; they are legally required.

Many cranes require specific certifications, such as the American National Standards Institute (ANSI) and the National Commission for the Certification of Crane Operators (NCCCO). Operators without these certifications pose a significant risk. According to industry data, sites adhering to strict regulations reduce accident rates by up to 30%.

Understanding local codes is crucial. Not all areas have the same requirements. Some locations have unique operational regulations that must be followed. Ignoring these can lead to fines and increased risk. Safety equipment also plays a key role. Operators should always wear proper gear, and cranes should have safety features such as limit switches and warning alarms. Investing time into understanding these requirements is essential for a safe work environment.

Construction Crane Safety Regulations Compliance

Related Posts

-

What is a Construction Crane? Understanding Types, Functions, and Uses in Modern Building Projects

-

Why Investing in Construction Cranes Boosts Project Efficiency and Reduces Costs

-

What is a Central Crane and How Does it Improve Construction Efficiency

-

Top 10 Tips for Safely Operating a Construction Crane

-

The Ultimate Guide to Choosing the Best Service Crane in 2025

-

2025 Top Trends in Hoist and Crane Technology for Industrial Applications