How to Choose the Right Industrial Crane for Your Needs?

Choosing the right industrial crane is crucial for efficient operations in various sectors. According to a report by Market Research Future, the global industrial crane market is projected to reach $30 billion by 2025. This growth underscores the importance of selecting the right crane tailored to specific needs.

Expert James Walker, a leading figure in the industrial crane industry, emphasizes, “Selecting an industrial crane is not just a purchase; it's an investment in safety and efficiency.” This statement highlights that the right crane can enhance productivity while minimizing risks. However, many companies struggle to make an informed choice. Factors such as load capacity, height, and frequency of use can complicate decisions.

A crane that fails to meet operational needs can lead to inefficiencies and hazards. Understanding the nuances of each type of industrial crane is essential. A single oversight can result in costly errors or accidents. It’s vital to reflect on your unique requirements before making a commitment to an industrial crane.

Understanding Different Types of Industrial Cranes Available in the Market

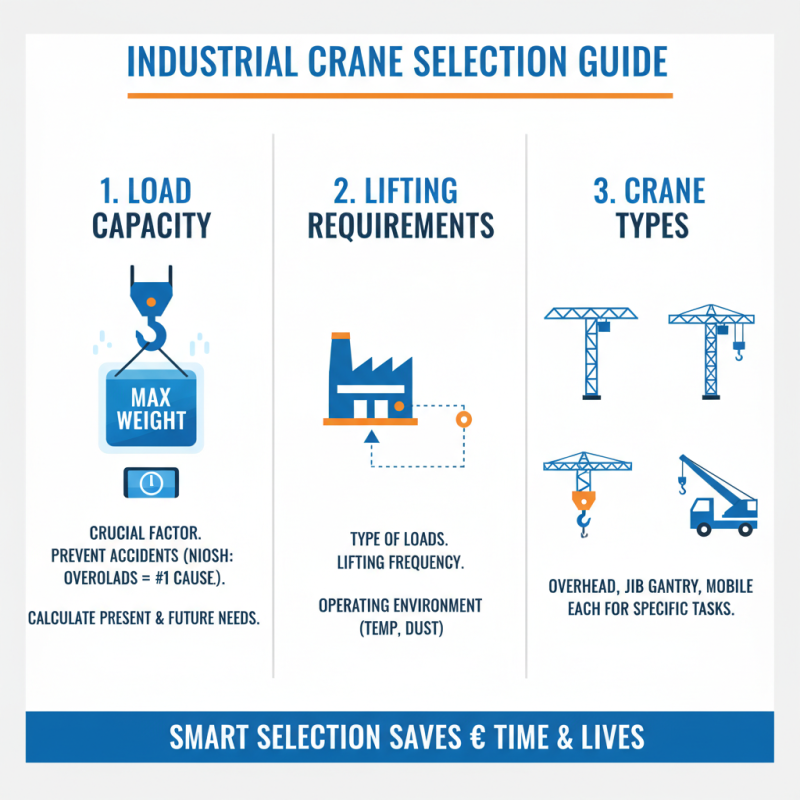

When selecting an industrial crane, understanding the types available is crucial. There are several main types, each designed for specific needs. Overhead cranes are primarily used in manufacturing facilities. They move heavy loads along a fixed path, making them effective for production lines. Jib cranes, with their rotating arm, offer flexibility. They can reach difficult areas and are often used in workshops.

Mobile cranes are another option, providing versatility. They can be moved from site to site, ideal for construction projects. However, they require proper setup and stabilization. Tower cranes are essential in large construction projects. They provide height and reach but come with complex assembly needs. Choosing the right type involves considering the environment, load capacity, and the crane’s intended use.

It’s also essential to think about safety features. Cranes must comply with industry standards. Regular inspections are necessary to prevent accidents. Reflecting on the operational challenges is vital. Each crane has limitations. Identifying the right balance between your needs and a crane's capabilities can be challenging.

Comparison of Different Types of Industrial Cranes

This chart illustrates the loading capacity of various types of industrial cranes commonly used in the market, helping businesses choose the right crane for their operational needs.

Evaluating Load Capacity and Specifications for Your Crane Needs

When selecting the right industrial crane, load capacity is a crucial factor. Understanding your lifting requirements can prevent costly mistakes. For example, a report by the National Institute for Occupational Safety and Health indicates that overloaded cranes are a leading cause of accidents. Calculate the maximum load you expect and consider future needs.

Tips: Always account for load dynamics. Rolling loads can add 10-20% to the required capacity. It’s wise to overestimate rather than underestimate your needs.

Specifications also matter. The height of the lift, boom reach, and operating environment should be defined early on. Different industries have varying standards. According to a recent industry study, cranes in construction need different specs than those used in manufacturing.

Tips: Check for the latest regulations concerning crane safety. Many facilities fail to meet compliance standards. Reflect on whether you're up-to-date with safety measures and specifications.

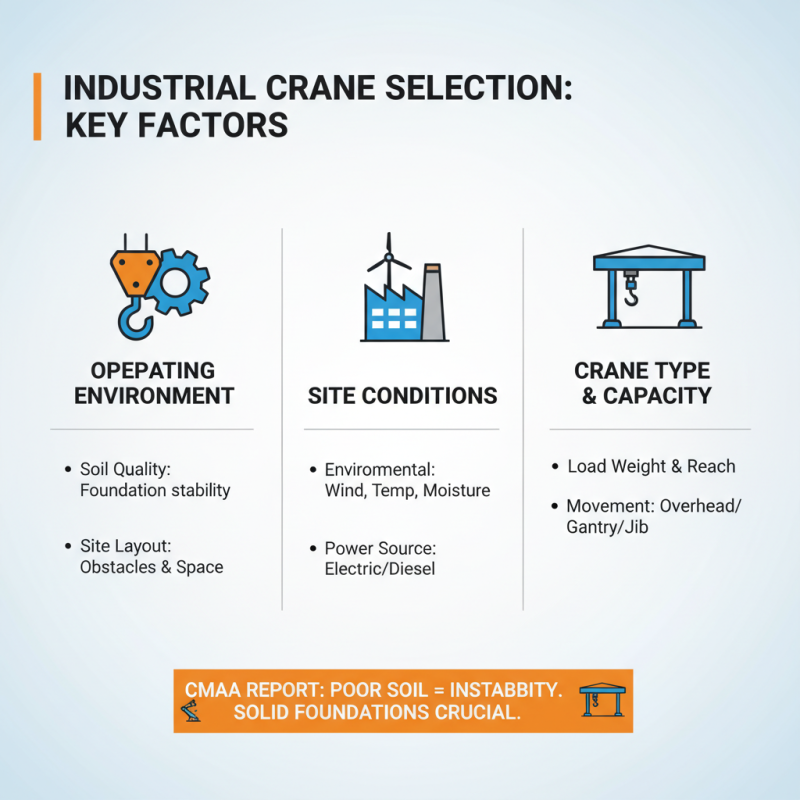

Assessing Operating Environment and Site Conditions for Crane Selection

Choosing the right industrial crane requires careful consideration of the operating environment and site conditions. Many factors affect crane performance, including soil quality, site layout, and environmental factors. For instance, a report from the Crane Manufacturers Association of America (CMAA) indicates that poor soil conditions can lead to crane instability. Heavy cranes require solid foundations.

Tips: Assess soil stability before installation. Consider soil tests for optimal safety.

Climate is another crucial factor. High winds or extreme temperatures can affect crane operations. For example, cranes cannot operate in wind speeds over 20 mph. According to the American National Standards Institute (ANSI), exceeding this limit can lead to accidents.

Tips: Monitor weather conditions daily. Develop a plan for adverse weather.

Lastly, the site layout should be analyzed. Clear paths are necessary for crane maneuverability. Obstructions can hinder operations and cause accidents. A site survey may reveal unanticipated challenges. Inadequate spacing can compromise safety. Investing in a thorough site assessment is essential. Cranes must be suited to specific tasks and environments.

Considering Safety Features and Compliance with Regulations

When choosing an industrial crane, safety features are vital. Cranes are powerful machines that require strict adherence to safety protocols. Evaluate the safety features your crane offers. Consider options like load limiters and emergency stop buttons. These features can prevent accidents and protect workers. Compliance with industry standards is essential for reducing risks. Understanding regulations can be challenging, but it is necessary.

Tips: Always check for certifications and ratings. Ensure the crane meets local safety regulations. Regular maintenance is crucial to keep safety features operational. Don’t overlook the importance of operator training. A well-trained operator reduces the chance of accidents.

Evaluate crane specifications before making a decision. Weight capacity, height, and reach matter. Inspect safety features like alarms and limit switches. Poor choice can lead to unsafe conditions. Reflect on these aspects carefully before purchasing. Choosing the right crane goes beyond just the cost. Prioritize safety and compliance above all.

How to Choose the Right Industrial Crane for Your Needs? - Considering Safety Features and Compliance with Regulations

| Crane Type | Load Capacity (tons) | Safety Features | Compliance Standards | Operating Environment |

|---|---|---|---|---|

| Overhead Crane | 5-50 | Emergency stop, overload protection | ASME B30.2 | Indoor |

| Mobile Crane | 10-100 | Stability alerts, safety locks | OSHA 1926.554 | Outdoor |

| Jib Crane | 0.5-15 | Load limit indicator, anti-collision system | ANSI B30.11 | Indoor |

| Tower Crane | 5-30 | Load moment indicator, anti-sway | BS 7121 | Construction sites |

| Forklift Crane | 1-10 | Fork positioning, load backrest | ANSI/ITSDF B56.1 | Warehouses |

Cost Factors and Maintenance Requirements When Choosing a Crane

When choosing an industrial crane, cost factors and maintenance requirements play a crucial role. The initial cost of cranes varies widely. A basic model might start around $15,000, while advanced ones can exceed $500,000. Many companies underestimate total costs. They focus primarily on purchase price without considering long-term expenses. Maintenance costs can average around 15% of the initial investment annually.

Routine maintenance is essential to ensure longevity. Neglecting it can lead to higher repair costs over time. For example, failing to lubricate parts regularly can cause wear and tear. This may result in unexpected downtime and significant losses. A recent study indicates that 70% of crane operators faced unplanned maintenance due to oversight.

Moreover, the type of crane impacts maintenance needs. Certain models require specialized technical knowledge for repairs. Limited availability of parts could also extend downtime. Companies should factor in these elements when making a decision. Straying from proper maintenance protocols can create risks. Frequent inspections are essential to avoid serious accidents.

Investing in a well-maintained crane saves money in the long run.

Related Posts

-

How to Choose the Right Industrial Crane for Your Construction Projects

-

What is an Industrial Crane? Types, Uses, and Key Considerations Explained

-

Maximizing Efficiency: How Grove Cranes Are Shaping the Future of Construction with 20% Increased Productivity

-

What is an Overhead Gantry Crane? Benefits, Uses, and Key Features Explained

-

10 Essential Tips for Choosing the Right Hoist Crane for Your Project

-

Top 10 Benefits of Using a 1 Ton Crane for Your Heavy Lifting Needs