What is an Industrial Crane? Types, Uses, and Key Considerations Explained

In the realm of heavy lifting and material handling, industrial cranes play a pivotal role, serving various sectors such as construction, manufacturing, and shipping. Defined as large machines designed to lift, move, and lower heavy loads, industrial cranes are vital for enhancing productivity and safety on job sites. According to industry expert Dr. Emily Thornton, "An industrial crane is not just a tool; it's the backbone of operational efficiency in environments that demand precision and power."

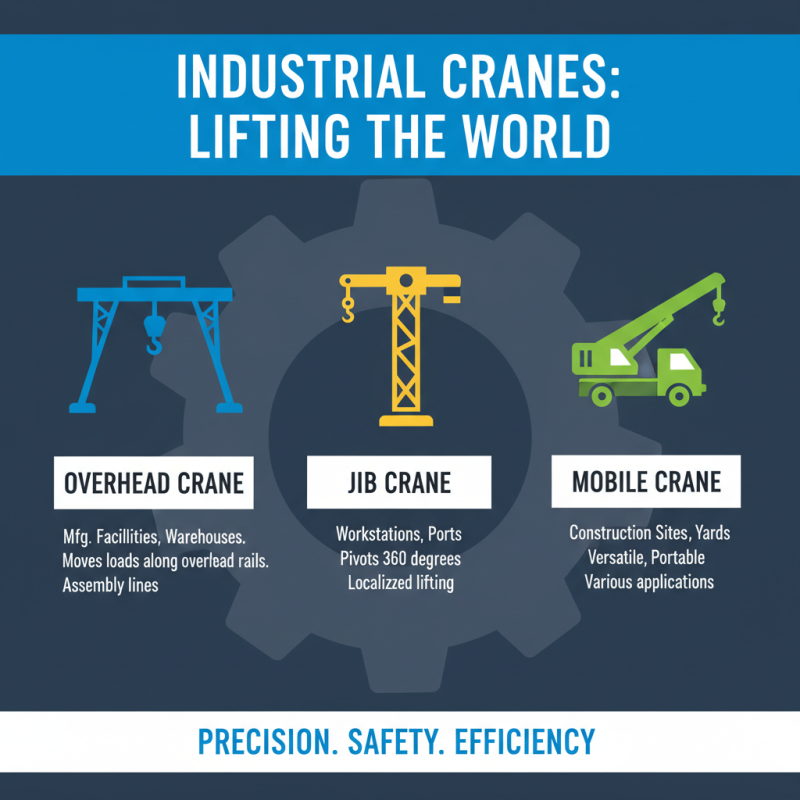

Understanding the types of industrial cranes available — from overhead and gantry cranes to mobile and tower cranes — is essential for any business looking to optimize their material handling processes. Each type has its specific use case, advantages, and limitations that must be carefully considered to ensure the right choice for a given task. As industries continue to evolve, so do the technologies and innovations surrounding industrial cranes, leading to improved performance and safety measures that address the dynamic needs of various applications.

In addition to exploring the types and uses of industrial cranes, key considerations such as load capacity, operational environment, and maintenance requirements are crucial for effective planning and implementation. By appreciating the complexities and significance of industrial cranes, businesses can make informed decisions that ultimately enhance their operational capabilities and ensure the safety of their workforce.

Definition and Functionality of Industrial Cranes

Industrial cranes are essential tools in various sectors, designed to lift and move heavy loads safely and efficiently. Defined as machines equipped with a hoist, hook, or other lifting mechanisms, they play a pivotal role in construction, manufacturing, and logistics. According to the "Industrial Crane Market Analysis Report" published by Mordor Intelligence, the global industrial crane market is projected to reach USD 45 billion by 2025, highlighting their significance in today's industrial landscape.

The functionality of industrial cranes extends beyond simple lifting; they can be specifically tailored to meet the diverse demands of different environments. For instance, overhead cranes are commonly utilized in factories and warehouses, facilitating the movement of materials across large distances. Meanwhile, mobile cranes are favored on construction sites for their versatility and ability to access hard-to-reach areas. A report by Research and Markets indicates that the demand for versatile cranes will drive growth in this sector, underlining the importance of selecting the right type of crane based on operational needs.

Tips: When considering the purchase or rental of an industrial crane, it is essential to assess the weight capacity required for your specific tasks. Additionally, understanding the site requirements, such as space and ground conditions, can significantly influence the efficiency and safety of crane operations. Lastly, regular maintenance and training programs for operators can enhance both safety and performance, ensuring that cranes function optimally throughout their lifespan.

Types of Industrial Cranes and Their Uses

This bar chart illustrates the usage percentage of various types of industrial cranes, highlighting their prevalence in different sectors. Overhead cranes are the most commonly used, accounting for 30% of all crane usage, followed by jib cranes and tower cranes.

Common Types of Industrial Cranes and Their Characteristics

Industrial cranes are essential tools in various sectors, designed to lift and move heavy loads with precision and safety. Among the numerous types of industrial cranes, the most commonly encountered include overhead cranes, jib cranes, and mobile cranes, each serving distinct functions and applications. Overhead cranes, often found in manufacturing facilities, feature a set of rails overhead, allowing them to move loads across a large area. These cranes are ideal for assembly lines and warehouse operations, where lifting heavy items from one point to another is crucial.

Jib cranes, on the other hand, are characterized by a horizontal arm or ‘jib’ that supports a moveable hoist. This type of crane allows for excellent maneuverability, making it suitable for loading and unloading materials in confined spaces. Jib cranes are commonly used in construction sites and workshops where flexibility is key. Mobile cranes, also a common type in the industrial sector, provide the advantage of mobility, allowing them to navigate various terrains. These cranes are well-suited for projects that require lifting heavy loads across different locations, such as in large construction and infrastructure projects. Each type of crane brings unique features and operational benefits tailored to specific industrial needs.

Applications of Industrial Cranes in Various Industries

Industrial cranes play a pivotal role across various sectors, significantly enhancing operational efficiency and safety. The construction industry, for instance, utilizes tower cranes and mobile cranes to lift heavy materials, ensuring that projects are completed more swiftly and with minimal risk of injury. According to the Global Construction Equipment Market report, the demand for cranes is expected to grow at a CAGR of over 5% from 2021 to 2026, driven by infrastructural developments and urbanization. In manufacturing, overhead cranes facilitate the seamless movement of components, thereby reducing downtime and optimizing production lines, as noted in the Machinery Market Analysis report.

In the shipping and logistics sectors, container cranes are integral for loading and unloading cargo efficiently. The International Maritime Organization (IMO) highlighted a significant increase in global trade, projecting that container terminal operations could see a rise in crane usage by 7% annually over the next five years. Similarly, in the automotive industry, gantry cranes assist in the assembly line, improving workflow and productivity by providing flexibility in material handling.

**Tips:** When selecting an industrial crane, consider the load capacity and reach needed for your specific application. Regular maintenance and operator training are essential for maximizing efficiency and ensuring safety in crane operations. Always assess the working environment and conditions since factors like space limitations and ground stability can significantly impact crane performance.

Key Considerations for Selecting and Using Industrial Cranes

When selecting and using industrial cranes, several key considerations must be taken into account to ensure safe and efficient operations. Firstly, understanding the load requirements is crucial. According to a report by the Industrial Crane Market Overview, the global crane market is expected to reach USD 50 billion by 2027, largely driven by increasing demand in construction and manufacturing sectors. It’s essential to select a crane that can comfortably handle the maximum load capacity while accounting for potential future increases in workload.

Additionally, the operational environment plays a significant role in the decision-making process. Factors such as space constraints, ground conditions, and potential hazards need to be analyzed. For instance, cranes operating in confined spaces require models that are compact yet powerful enough to perform tasks effectively. A study by the International Association of Geophysical Contractors highlights that more than 30% of crane-related accidents occur due to improper assessment of the working environment. Therefore, adequate training and knowledge of the workspace is paramount for ensuring safety and optimizing performance.

Furthermore, regular maintenance and adherence to safety standards are indispensable. The Occupational Safety and Health Administration (OSHA) underscores that proper inspections could prevent approximately 75% of crane-related incidents. Establishing a comprehensive maintenance schedule and fostering a culture of safety can significantly enhance the longevity of the crane and the safety of operators. Evaluating all these factors ultimately contributes to more efficient operations and mitigates risks associated with industrial lifting activities.

Safety Protocols and Maintenance Practices for Industrial Cranes

Safety protocols and maintenance practices are critical components in the operation of industrial cranes, ensuring not only the longevity of the equipment but also the safety of personnel on the job site. According to the Occupational Safety and Health Administration (OSHA), improper use of cranes accounts for a significant portion of workplace accidents, which results in injuries and financial losses. It is estimated that effective safety training and rigorous maintenance protocols can reduce incidents by up to 29%. Regular inspections, adherence to load limits, and ensuring proper rigging practices are essential to mitigate risks associated with crane operations.

Maintenance practices are equally important, as studies have shown that poorly maintained cranes can lead to catastrophic failures. The National Institute for Occupational Safety and Health (NIOSH) highlights that regular preventive maintenance can decrease equipment downtime by around 20% and extend the lifespan of crane components. Maintenance should include routine checks of hydraulic systems, structural integrity, and electrical components, as well as thorough documentation of all inspections and repairs. By fostering a culture of safety and stringent maintenance programs, employers can create a safer working environment while improving operational efficiency and reducing potential legal liabilities associated with crane operation.

Related Posts

-

10 Essential Tips for Choosing the Right Hoist Crane for Your Project

-

How to Choose the Right Industrial Crane for Your Construction Projects

-

Maximizing Efficiency: How Grove Cranes Are Shaping the Future of Construction with 20% Increased Productivity

-

What is a Construction Crane? Understanding Types, Functions, and Uses in Modern Building Projects

-

Why Investing in Construction Cranes Boosts Project Efficiency and Reduces Costs

-

2025 Top Trends in Hoist and Crane Technology for Industrial Applications