Top 10 Overhead Gantry Crane Benefits and Applications You Should Know

In today's fast-paced industrial landscape, the efficiency and safety of material handling processes have become paramount. The overhead gantry crane, a vital piece of equipment in various sectors such as construction, manufacturing, and shipping, offers significant advantages that can transform operational capabilities. According to a recent report by the International Journal of Industrial Ergonomics, the use of overhead cranes can improve productivity by up to 30%, while also reducing the risk of workplace injuries by minimizing the manual handling of heavy loads.

Expert in material handling solutions, Dr. James W. Gregory, emphasizes the transformative potential of these cranes: "Overhead gantry cranes not only enhance productivity but also ensure a safer working environment, which is increasingly crucial in today's industries." Beyond enhancing safety and efficiency, these cranes are versatile and can be adapted to various tasks, making them indispensable in many operational settings. Their ability to streamline workflows and reduce labor costs positions them as essential investments for companies looking to elevate their logistical operations. As we explore the top ten benefits and applications of overhead gantry cranes, it is clear that these machines will continue to play a critical role in shaping the future of material handling.

Benefits of Overhead Gantry Cranes in Industrial Settings

Overhead gantry cranes have become essential in various industrial settings due to their numerous benefits, enhancing operational efficiency and safety in workplaces. According to a recent industry report by Grand View Research, the global overhead crane market is projected to reach approximately $4.5 billion by 2027, growing at a CAGR of 4.2%. This growth highlights the increasing reliance on these cranes for heavy lifting and material handling across sectors such as manufacturing, construction, and logistics.

One of the primary advantages of overhead gantry cranes is their ability to maximize workspace utilization. Unlike traditional floor cranes, which require significant ground space for operation, gantry cranes operate above ground, allowing for the optimization of workspace. Additionally, the flexibility of these cranes enables them to move along a set track, providing dynamic load lifting and transport capabilities, crucial for industries where efficiency is key. Furthermore, their robust design ensures durability and longevity, which is supported by data from the Industrial Truck Association, indicating that effective handling equipment can improve productivity levels by up to 25% and significantly reduce downtime in operations.

In terms of safety, overhead gantry cranes diminish the risks associated with manual lifting and material handling. The National Safety Council reports that material handling incidents account for a significant percentage of workplace injuries, highlighting the necessity for mechanized solutions. By automating the lifting process, businesses not only protect their workforce but also enhance overall operational safety, leading to lower insurance costs and improved morale among employees. The transformative impact of overhead gantry cranes in industrial settings cannot be overstated, positioning them as an invaluable asset for modern enterprises.

Benefits of Overhead Gantry Cranes in Industrial Settings

Improved Efficiency and Productivity with Gantry Cranes

Overhead gantry cranes are increasingly becoming essential tools in various industrial settings due to their ability to enhance efficiency and productivity. These cranes facilitate the seamless movement of heavy loads across large areas, reducing the time and labor required for manual handling. By offering increased mobility and flexibility, gantry cranes can significantly streamline workflows, allowing for smoother operations in factories, warehouses, and construction sites.

When implementing gantry cranes, it’s crucial to consider the layout of your workspace. Ensure that there is sufficient clearance and that the path of movement is unobstructed. This can maximize the crane's potential and minimize downtime caused by obstacles. Additionally, regular maintenance checks can prevent unexpected equipment failures, ensuring that your operations remain uninterrupted and efficient.

Another tip for maximizing the benefits of overhead gantry cranes is to invest in operator training. Skilled operators can make the most of the crane's features while adhering to safety protocols, further enhancing overall productivity. Providing ongoing training can also keep your team up to date with the latest safety practices and operational techniques, resulting in a safer and more efficient workplace.

Versatility of Overhead Gantry Cranes in Various Industries

Overhead gantry cranes are known for their adaptability across diverse industries, making them invaluable tools in various operational settings. Their unique structure allows them to traverse large areas, lifting and moving heavy loads with precision and ease, contributing significantly to improving productivity and safety. In manufacturing, they play a crucial role in assembly lines, facilitating the movement of materials and components, thus streamlining workflows. Their robust design and customizable features enable them to handle irregularly shaped items and products of varying weights, catering to specific industry needs.

In the construction sector, overhead gantry cranes are indispensable for lifting heavy equipment and materials to elevated positions, ensuring that projects progress smoothly and efficiently. Their ability to operate in tight spaces and on uneven ground enhances their versatility, making them ideal for construction sites where traditional lifting equipment may fall short. Moreover, in the shipping and logistics industry, these cranes are essential for loading and unloading cargo containers, maximizing throughput and minimizing downtime. This versatility not only improves operational efficiency but also enhances safety and reduces the risk of injuries related to manual lifting.

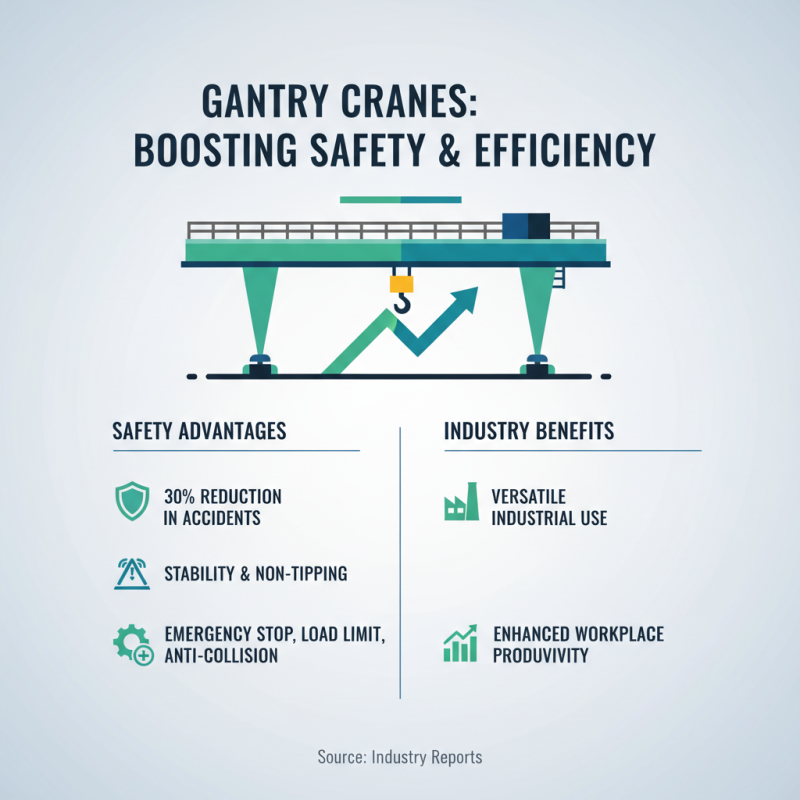

Safety Features and Advantages of Using Gantry Cranes

Gantry cranes have become essential in various industries due to their numerous safety features and advantages. One of the most significant benefits is their ability to enhance workplace safety. According to industry reports, facilities that utilize gantry cranes have experienced a 30% reduction in workplace accidents, largely due to their stability and the ability to lift heavy loads without the risk of tipping over. Additionally, gantry cranes often come equipped with features such as emergency stop buttons, load limit switches, and anti-collision systems, all of which contribute to a safer working environment.

Safety is further bolstered by the versatility of gantry cranes, which can be used in a variety of applications, from construction sites to manufacturing plants. This adaptability allows operators to tailor their lifting solutions to specific tasks, minimizing the risks associated with improper load handling. Furthermore, the ease of operation and training requirements for gantry cranes make them accessible to a broader range of personnel, reducing the likelihood of accidents caused by operator error.

Tips: Always ensure that operators are properly trained and certified before using gantry cranes. Regular maintenance checks and compliance with safety regulations can significantly prolong the lifespan of the equipment and enhance safety. Additionally, implementing a clear communication protocol among workers operating in proximity to gantry cranes will further enhance safety and minimize risks during high-lift operations.

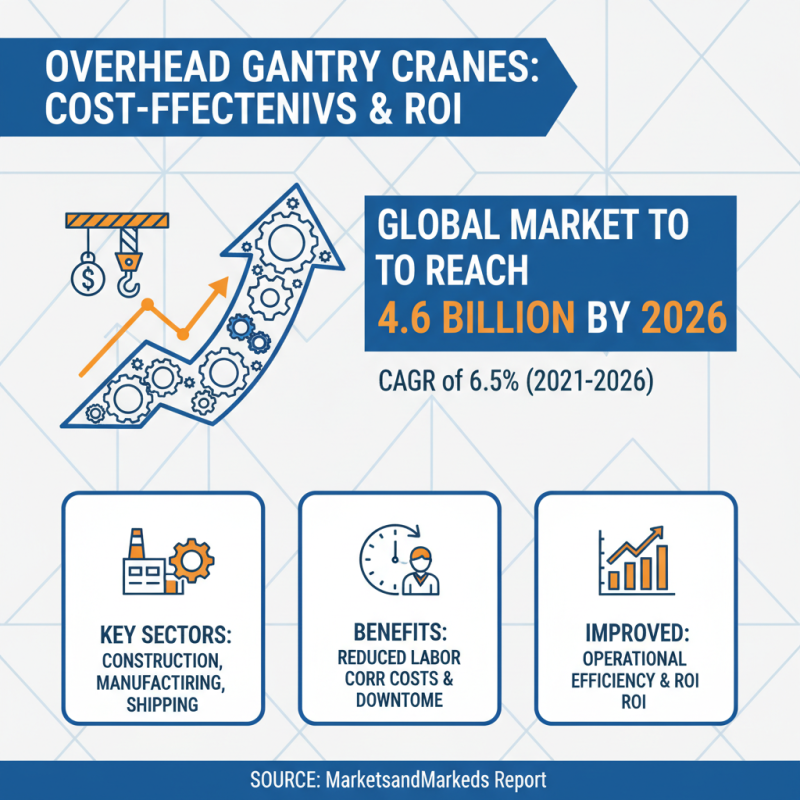

Cost-Effectiveness and Return on Investment of Gantry Cranes

Overhead gantry cranes are increasingly recognized for their cost-effectiveness and superior return on investment (ROI) in various industries. According to a report by MarketsandMarkets, the global gantry crane market is projected to reach $4.6 billion by 2026, reflecting a compound annual growth rate (CAGR) of 6.5%. This growth underscores the economic advantages these cranes provide, particularly in sectors such as construction, manufacturing, and shipping. Their ability to operate in diverse environments while facilitating efficient material handling significantly reduces labor costs and downtime, leading to improved operational efficiency.

Moreover, a study by the International Journal of Advanced Manufacturing Technology highlights that businesses utilizing overhead gantry cranes can experience labor savings upwards of 25%. This reduction is primarily attributed to the cranes' capacity to handle heavy loads safely, which minimizes the need for excessive manpower. Additionally, by optimizing workflow and reducing the time needed for loading and unloading, companies can achieve faster project completions and enhance overall productivity. The initial investment in a gantry crane is often recouped within a few years, making it a financially sound decision for enterprises looking to streamline their operations while maximizing their financial returns.

Related Posts

-

2025 Guide: How to Choose the Best 1 Ton Gantry Crane for Your Needs

-

2025 Guide: How to Choose the Right Mobile Gantry Crane for Your Project

-

10 Essential Tips for Choosing the Right Hoist Crane for Your Project

-

How to Choose the Right Industrial Crane for Your Construction Projects

-

Top 5 Benefits of Using a 2 Ton Gantry Crane for Your Projects

-

What is an Industrial Crane? Types, Uses, and Key Considerations Explained