Top 10 Tips for Safely Operating a Construction Crane

Operating a construction crane is a task that demands the utmost attention to safety. The Construction Industry Institute reports that crane accidents account for a significant portion of construction-related fatalities. According to industry expert John Smith, “Proper training and safety protocols are vital when operating a construction crane.” His words highlight the need for rigorous safety measures.

Despite advancements in technology, human error remains a leading cause of accidents. A 2022 safety report indicated that over 50% of crane incidents resulted from inadequate training. Workers often overlook basic safety checks, leading to potentially tragic outcomes. Knowing how to safely operate a construction crane involves more than understanding machinery; it requires a culture of safety and diligence.

Inadequate safety measures can lead to heavy financial losses, aside from the risks to human life. As experts stress, a well-informed operator is a safer operator. Emphasizing training and regular safety drills can drastically reduce accidents. It's clear that improving crane operation safety should be a collective priority.

Understanding Crane Types and Their Safe Operation Guidelines

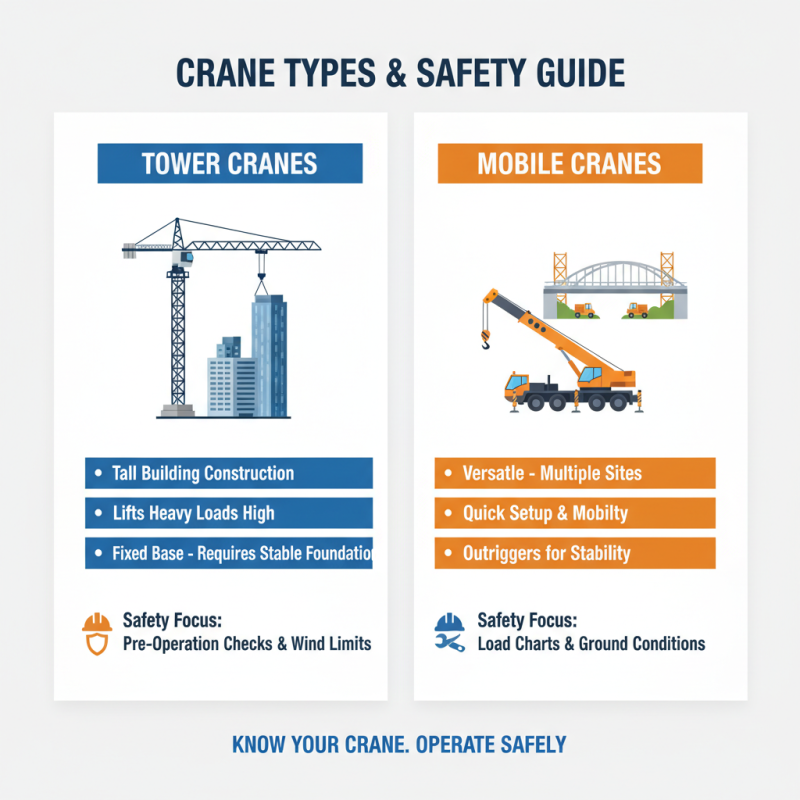

Understanding different types of cranes is essential for safe operation. Tower cranes are commonly used for tall building construction. Their height allows them to lift heavy loads high into the air. Mobile cranes are versatile and can move from job site to job site. They are great for projects requiring flexibility. Each crane type comes with specific safety guidelines that operators must follow.

Operators should know their crane's unique features. Not all cranes handle loads the same way. For example, the load chart provides crucial information. It helps determine the maximum capacity for various angles and configurations. Misunderstanding these specifications can lead to dangerous situations. Always check the crane's load limits before operating. Even minor oversights can cause significant issues.

Training and communication are vital. Operators shouldn't work alone. They need a signal person to guide them during lifts. Inadequate communication can lead to accidents. Regular checks and maintenance of cranes are necessary. Issues with mechanical components can arise unexpectedly. Conduct daily inspections to ensure safety. Operators should not rush through these procedures. Safety must always come first.

Pre-Operational Safety Checks for Construction Cranes

Before operating a construction crane, conducting pre-operational safety checks is essential. Inspecting the crane’s structure and components can prevent serious accidents. Start by checking the crane's physical condition. Look for structural damage, such as cracks or bends. Ensure that all safety guards are in place. A simple visual inspection can catch many issues.

Next, assess the hydraulic system. Confirm there are no leaks or damages to hoses or fittings. Fluid levels should be adequate. This can help the crane perform efficiently. Check the control systems, too. Test controls to ensure they respond correctly without hesitation. Workers often overlook minor control issues, which can lead to larger problems during operation.

Additionally, pay attention to environmental factors. Inspect the working area for potential hazards. Obstacles, overhead power lines, or uneven ground can create dangerous situations. Every detail matters. Reflect on the importance of these checks. A moment of negligence can lead to accidents that affect everyone on-site. Safety should never be compromised.

Best Practices for Rigging Loads Securely on Cranes

Rigging loads securely on cranes is crucial for safety. Proper rigging helps prevent accidents and damages. Use strong, inspected slings. Check for wear and tear. A frayed sling can break, leading to dangerous situations. Select rigging gear that suits the load's weight and shape. Understand the center of gravity. This knowledge helps stabilize the load during lifting.

Always use appropriate rigging techniques. Use choker hitches, basket hitches, or vertical hitches as needed. Each method has its purpose. Misuse of rigging types can lead to failures. Inspect all connections before lifting. A simple overlooked snap can result in catastrophic failure. Communication among crew members is vital. Establish clear signals and use radios.

Rigging requires constant attention and reflection. Mistakes can happen. Even experienced operators can overlook details. Regular training and drills can improve awareness. Safety checklists can help ensure nothing is missed. It’s a continuous learning process. Even small adjustments can make a big difference in safe operations.

Top 10 Tips for Safely Operating a Construction Crane - Best Practices for Rigging Loads Securely on Cranes

| Tip No. | Safety Tip | Description | Importance |

|---|---|---|---|

| 1 | Regular Inspection | Conduct daily inspections of crane and rigging equipment. | Ensures all equipment is in safe operating condition. |

| 2 | Use Proper Rigging | Select appropriate rigging gear for the load type. | Prevents load slippage and accidents. |

| 3 | Communicate Clearly | Use hand signals or radios to communicate among the team. | Reduces the chance of misunderstandings during operation. |

| 4 | Load Weight Verification | Always verify the weight of the load before lifting. | Prevents exceeding crane capacity, reducing risk of failure. |

| 5 | Establish Load Limits | Know and adhere to lift capacity limitations. | Maintains structural integrity and safety. |

| 6 | Clear the Area | Ensure the area under the load is clear of personnel and obstacles. | Minimizes risk of injury from falling loads. |

| 7 | Wind Conditions Check | Evaluate wind conditions prior to lift. | Prevents load sway and loss of control. |

| 8 | Properly Store Equipment | Store crane and rigging gear in a safe, organized manner. | Ensures equipment longevity and readiness. |

| 9 | Training and Certification | Ensure all operators are trained and certified. | Reduces incident rates and improves operational knowledge. |

| 10 | Be Aware of Surroundings | Maintain awareness of nearby structures, lines, and hazards. | Avoids accidents related to environmental factors. |

Communication Protocols for Crane Operation Teams

Effective communication is crucial for crane operation teams. Miscommunication can lead to accidents, especially in construction sites. According to the CDC, about 22% of crane-related fatalities involve communication failures. It's vital to establish clear protocols among team members. Use standardized hand signals and verbal commands. This ensures everyone understands their roles.

Tip: Always have a designated signaler. This person oversees the operation and communicates with the crane operator. Misunderstandings can arise if multiple people give commands. Teams should practice scenarios regularly. This reinforces the communication protocols and can identify weaknesses.

Moreover, maintaining an open line for feedback is essential. Team members should feel empowered to voice concerns. If someone feels unclear about a command, they should speak up immediately. Studies show that fostering open communication leads to a 30% reduction in accidents. Building a team culture that prioritizes safety can drastically improve outcomes. Remember, safety is a shared responsibility.

Emergency Procedures and Safety Measures in Crane Operation

Operating a construction crane requires rigorous attention to safety protocols. In high-stakes environments, emergency procedures are vital. Workers must know how to respond to unexpected situations. Ensure all operators are trained in these protocols. Proper practice can save lives.

One crucial tip is to always check equipment before use. Regular inspections help identify potential issues early. If something seems off, report it. Waiting can lead to catastrophic consequences. Another key point is clear communication among crew members. Use hand signals and radios effectively to avoid misunderstandings.

In an emergency, time is of the essence. Establish a clear evacuation plan. Always have a first aid kit accessible. Keep emergency contacts on hand. Make sure everyone knows their role during a crisis. Regular drills can enhance readiness. Preparing for the unpredictable can reduce panic and streamline response efforts. Just remember, even the best-laid plans need flexibility.

Related Posts

-

What is a Construction Crane? Understanding Types, Functions, and Uses in Modern Building Projects

-

What is a Central Crane and How Does it Improve Construction Efficiency

-

Why Investing in Construction Cranes Boosts Project Efficiency and Reduces Costs

-

Maximizing Efficiency: How Grove Cranes Are Shaping the Future of Construction with 20% Increased Productivity

-

How to Choose the Right Industrial Crane for Your Construction Projects

-

What is an Industrial Crane? Types, Uses, and Key Considerations Explained