2025 Top Trends in Hoist and Crane Technology for Industrial Applications

As industries evolve, the technology surrounding hoist and crane systems is keeping pace, unlocking new efficiencies and capabilities across various applications. According to a recent report from MarketsandMarkets, the global crane and hoist market is projected to reach USD 25.79 billion by 2025, growing at a CAGR of 4.5%. This indicates not only a robust demand for these systems but also highlights the critical role they play in enhancing operational productivity in manufacturing, construction, and logistics sectors.

Industry expert Dr. Emily Jacobs, a leading figure in crane technology innovation, emphasizes the importance of staying ahead in this fast-evolving landscape. She states, "The integration of advanced automation and smart technologies in hoist and crane systems will be paramount for reducing operational costs and improving safety standards." This insight underscores the need for industries to adopt cutting-edge hoist and crane solutions that leverage emerging technologies, ensuring they remain competitive in a rapidly changing market.

As we delve into the top trends for 2025, it is clear that advancements in efficiency, safety, and automation are on the horizon. Understanding these trends will equip businesses with the knowledge necessary to invest wisely in their hoist and crane systems, ultimately driving their success in the industrial arena.

2025 Innovations in Hoist and Crane Technology for Industrial Use

The global automotive crane market is expected to reach $12.61 billion by 2024 and grow to $197.3 billion by 2033, demonstrating a compound annual growth rate (CAGR) of 5.10% from 2025 to 2033. As we navigate through 2025, the industry is witnessing a significant shift towards intelligent technologies aimed at enhancing operational safety and efficiency. One of the most notable innovations is the implementation of AI-based collision avoidance systems, which are enabling cranes to operate with a "zero collision" assurance. This advancement is pivotal in elevating industry safety standards, aligning with broader initiatives to modernize construction operations.

In response to increasing market demands, the engineering crane sector is rapidly embracing intelligent transformation driven by technological breakthroughs and evolving consumer needs, particularly under the guidance of the "14th Five-Year Plan." With the introduction of improved performance characteristics and safety features, the crane industry is set to propel forward. Automation, remote control systems, and advanced safety protocols are being integrated, allowing operators to manage crane operations with enhanced precision and efficiency. The period from 2025 to 2034 will be critical in shaping a future where cranes are not only more efficient but also safer, underscoring a remarkable evolution in industrial applications.

Predictive Maintenance Trends in Hoist and Crane Systems

Predictive maintenance is rapidly becoming a cornerstone in the operation of hoist and crane systems within industrial applications. By leveraging advanced data analytics and machine learning algorithms, companies can anticipate equipment failures before they occur, significantly reducing costly downtime. Sensors installed on hoisting equipment collect real-time data on various parameters such as load conditions, vibrations, and temperature, enabling predictive models to diagnose the health of these systems accurately.

As we move toward 2025, the integration of IoT (Internet of Things) technologies is expected to enhance the capabilities of predictive maintenance in this sector. Connectivity allows for seamless data transfer and remote monitoring, empowering maintenance teams with insights into equipment performance from anywhere. This trend not only optimizes maintenance schedules but also extends the lifespan of hoists and cranes, ultimately contributing to safer, more efficient industrial operations. The evolution of predictive maintenance signifies a transformative shift that will shape the future of material handling and lifting technologies.

Integration of IoT Solutions in Crane and Hoist Operations

The integration of Internet of Things (IoT) solutions in crane and hoist operations is set to redefine the landscape of industrial applications by 2025. According to a recent report by MarketsandMarkets, the IoT in the manufacturing sector is expected to grow from USD 11.1 billion in 2020 to USD 23.5 billion by 2025, nearly a double in market size. This significant growth signals a shift towards more automated and efficient operations within crane and hoist systems. By equipping cranes with IoT sensors, real-time data can be gathered regarding load weight, operational efficiency, and maintenance needs, allowing for proactive decision-making and enhanced safety.

Furthermore, the adoption of IoT-driven analytics is projected to increase the operational efficiency of cranes and hoists by up to 30%, as reported by a study from the International Journal of Industrial Science. The implementation of predictive maintenance models, powered by IoT data, can drastically reduce downtime and operational costs. The ability to monitor equipment condition remotely using IoT technology enables companies to schedule maintenance only when necessary, rather than adhering to a rigid timetable. This not only optimizes productivity but also extends the lifespan of the machinery, making it a crucial investment for industries looking to improve their operational capabilities in an increasingly competitive environment.

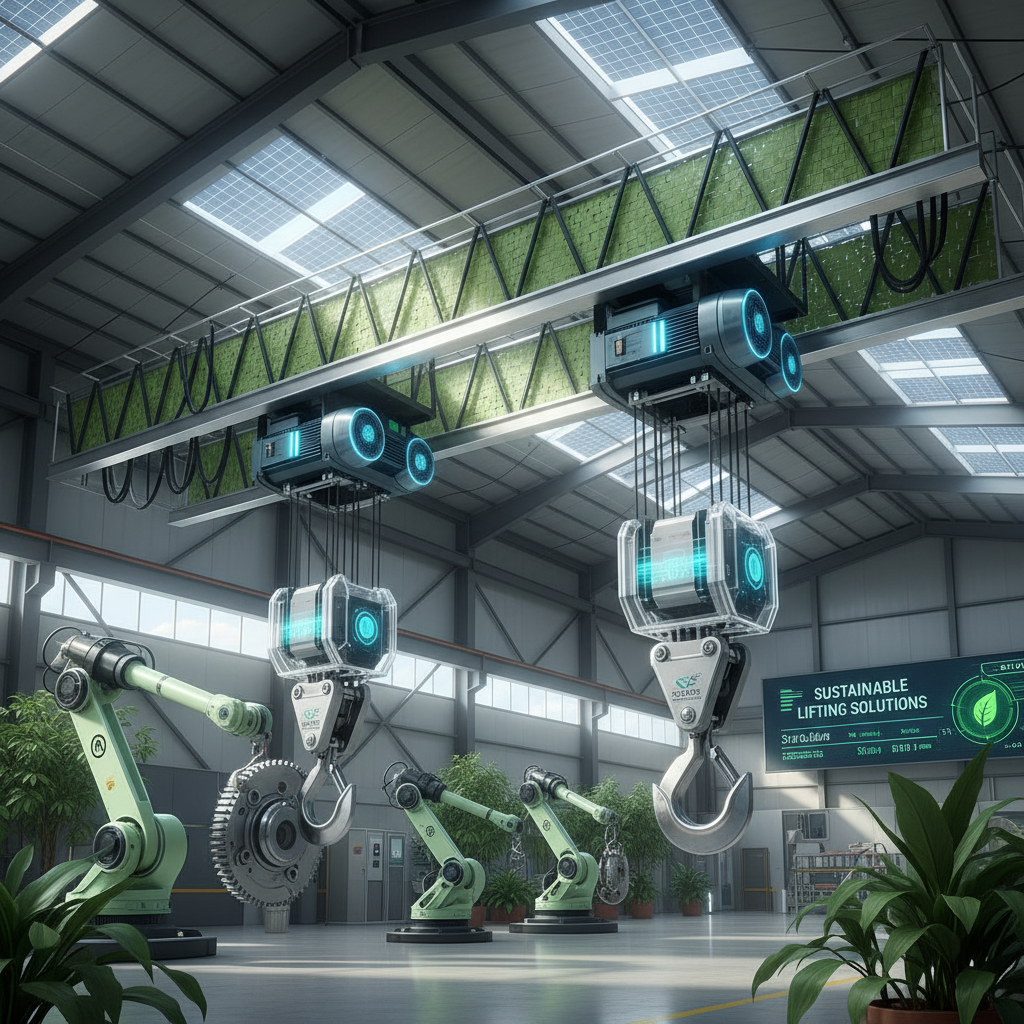

Sustainable Practices and Materials in Hoist and Crane Manufacturing

The future of hoist and crane technology is heavily influenced by sustainable practices and materials. Manufacturers are increasingly turning to eco-friendly materials, such as recycled metals and biocomposites, which not only reduce the carbon footprint but also enhance the structural integrity of hoisting equipment. Innovations in energy-efficient motors and regenerative drives are paving the way for cranes that consume less power and have a longer operational lifespan. This shift towards sustainability is not just a trend; it is becoming a necessity in industrial applications where minimizing environmental impact is paramount.

Tip: When selecting a hoist or crane, consider the manufacturer's commitment to sustainable practices. Look for certifications or eco-labels that indicate the use of recycled or renewable materials in production.

Additionally, the integration of smart technology is revolutionizing the manufacturing process. Advanced software solutions allow for the optimization of resources and reduction of waste during production. These smart systems enable real-time monitoring of energy consumption and maintenance needs, ensuring that equipment runs efficiently while adhering to environmental standards. As industries strive for greener operations, investing in cranes equipped with these technologies can significantly contribute to achieving sustainability goals.

Tip: Regularly assess your crane systems for efficiency and sustainability. Small changes in operation can lead to significant reductions in energy consumption and operational costs in the long run.

Emerging Automation Technologies in Industrial Hoisting Applications

The evolution of automation technologies in industrial hoisting applications is transforming the landscape of manufacturing and construction sectors. As industries increasingly adopt advanced automation solutions, the demand for more efficient and safer lifting mechanisms is surging. According to a recent report by MarketsandMarkets, the global industrial crane market is projected to reach $22.8 billion by 2025, growing at a CAGR of 6.1%. This growth is largely fueled by the integration of IoT and AI technologies, enhancing operational monitoring, predictive maintenance, and overall efficiency.

Emerging technologies such as artificial intelligence and machine learning are paving the way for more intelligent hoisting systems. These systems can analyze real-time data to optimize load management and reduce downtime. For instance, research from the International Society of Automation indicates that incorporating advanced analytics can improve equipment effectiveness by up to 15%, significantly lowering operational costs. Furthermore, smart hoisting solutions equipped with sensors can detect anomalies and adjust performance dynamically, ensuring safety and compliance with stringent regulatory standards. As these trends continue to develop, the industrial hoisting sector will surely witness a paradigm shift towards greater automation and intelligence in lifting operations.

2025 Top Trends in Hoist and Crane Technology for Industrial Applications

Related Posts

-

10 Essential Tips for Choosing the Right Hoist Crane for Your Project

-

What is a Construction Crane? Understanding Types, Functions, and Uses in Modern Building Projects

-

What is a Central Crane and How Does it Improve Construction Efficiency

-

Why Investing in Construction Cranes Boosts Project Efficiency and Reduces Costs

-

Maximizing Efficiency: How Grove Cranes Are Shaping the Future of Construction with 20% Increased Productivity

-

What is a Truck Crane and How Does it Work