The Ultimate Guide to Choosing the Best Service Crane in 2025

In the ever-evolving landscape of industrial equipment, the selection of the right service crane has become a pivotal factor for operational efficiency and safety in various sectors. As we approach 2025, businesses are faced with an array of choices, each boasting different features, capabilities, and technologies. Understanding the essential criteria for choosing the best service crane is crucial for maximizing productivity while ensuring compliance with safety standards.

This guide aims to equip decision-makers with the knowledge necessary to navigate the complexities of service crane options available in the market. From load capacity to mobility features, we will delve into the key attributes to consider, ensuring that organizations can identify a crane that aligns not only with their operational needs but also with the evolving industry standards. Whether for construction sites, maintenance projects, or warehouse operations, selecting the ideal service crane can profoundly impact overall efficiency and effectiveness.

Understanding the Different Types of Service Cranes Available in 2025

In 2025, the landscape of service cranes will continue to evolve, offering a variety of types tailored to specific industry needs. The most common types include mobile cranes, truck-mounted cranes, and crawler cranes. According to industry reports, mobile cranes dominate the market due to their versatility and ease of transport. They are ideal for construction sites where maneuverability is key, often boasting a lifting capacity ranging from 15 to 1,200 tons.

Truck-mounted cranes are favored for their quick setup and ability to be driven on public roads, making them essential for urban projects. These cranes typically offer lifting capacities between 20 to 400 tons. On the other hand, crawler cranes, equipped with tracks for stability, excel in heavy lifting applications, especially in rough terrains. Recent data indicates that the demand for crawler cranes is projected to grow by 7% annually, primarily driven by infrastructure development in emerging markets.

Furthermore, as industries become more focused on sustainability and efficiency, service cranes with advanced technology such as remote controls and smart sensors are anticipated to see increased adoption. Reports from the International Crane and Specialized Transport Association (ICSTA) suggest that smart crane technologies could enhance operational efficiency by up to 30%, revolutionizing how cranes are integrated into project workflows.

Key Factors to Consider When Selecting a Service Crane

When selecting a service crane, several key factors must be taken into account to ensure that you invest in the right equipment for your needs. First and foremost, consider the capacity of the crane. It’s essential to determine the maximum weight that the crane will need to lift. Match the crane's capacity with your typical load requirements, taking into account any potential variations in weight. A crane that is undersized may compromise safety, while an oversized crane may incur unnecessary costs and complications.

Another crucial factor is the crane's reach and height. Evaluate the specific projects you will be undertaking to identify the required lifting height and horizontal reach. This assessment helps ensure that the crane can maneuver effectively in the operating environment, particularly in tight spaces or at varying heights.

Additionally, pay attention to the crane's mobility and setup time, especially if you will frequently transport it between job sites. A crane that is easy to transport and quick to set up can significantly enhance efficiency and productivity in operations. Make sure to also scrutinize safety features, as they are paramount in preventing accidents and ensuring compliance with regulations.

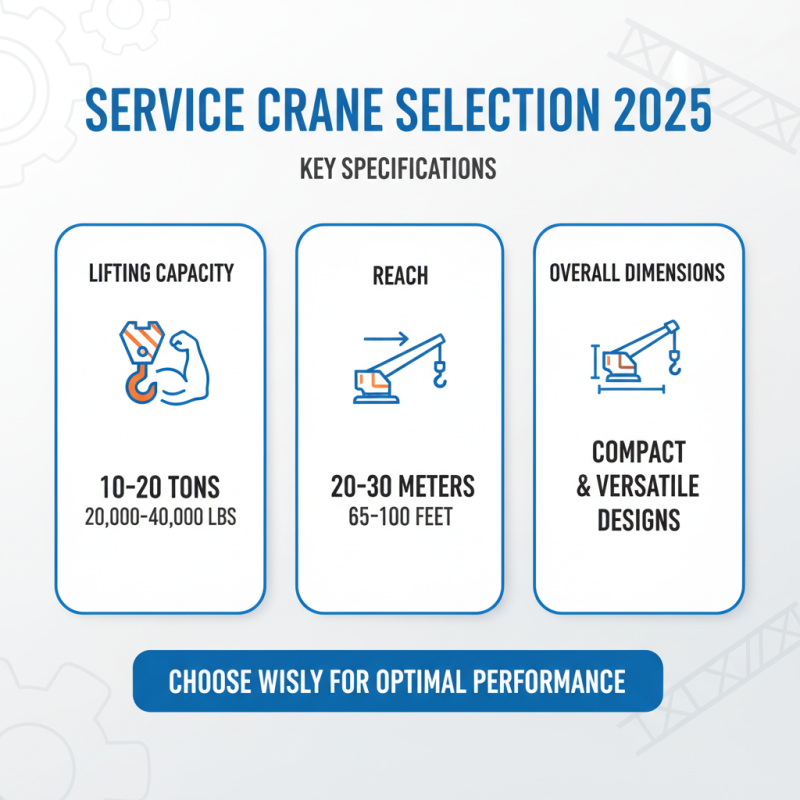

Comparing Features and Specifications of Leading Service Crane Models

When selecting a service crane in 2025, it is essential to compare the features and specifications of leading models to ensure the best choice for your needs. Key specifications to consider include lifting capacity, reach, and overall dimensions. A thorough analysis of these features will help determine how well a crane can perform in various environments, whether for construction sites, maintenance work, or industrial service.

Furthermore, evaluating additional factors such as ease of operation, safety features, and maintenance requirements is crucial. Many modern service cranes come equipped with advanced technology, such as automated controls and load monitoring systems, which significantly enhance operational efficiency. Additionally, look for cranes that offer versatility in attachments and configurations to maximize their utility across different tasks. This comprehensive comparison will enable potential buyers to make informed decisions, aligning their choice with specific operational demands and ensuring long-term satisfaction with their investment.

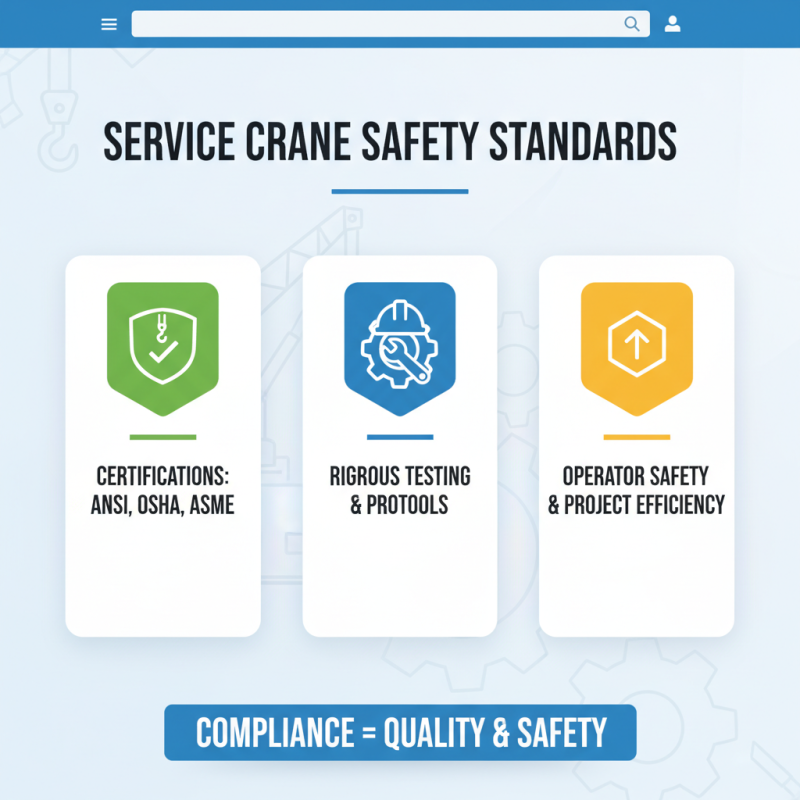

Evaluating Safety Standards and Certifications for Service Cranes

When selecting a service crane, evaluating safety standards and certifications is paramount to ensuring both operator safety and project efficiency. Compliance with industry regulations is not merely about meeting legal requirements but about establishing a reliable framework for quality and safety. Service cranes should adhere to established safety standards such as ANSI, OSHA, or ASME, which dictate operational guidelines and safety measures. Such certifications often indicate that the equipment has undergone rigorous testing and meets stringent safety protocols.

Tips: Always look for cranes that come with a clear display of their certifications. This can provide peace of mind that the crane has passed the necessary inspections and is capable of handling specific loads safely. Additionally, inquire about the manufacturer’s adherence to safety protocols during the crane's design and production phases.

Another crucial aspect is the crane’s regular maintenance and inspection records. A crane that is consistently maintained is less likely to experience malfunctions, which could lead to accidents. Make sure to review the service history and any certifications related to maintenance programs that the crane has undergone.

Tips: Prioritize cranes that have a documented maintenance schedule. This helps ensure that the equipment remains in top condition and complies with safety standards throughout its operational life. The safer the crane, the more efficient your operations will be.

Budgeting: Cost Considerations for Purchasing a Service Crane in 2025

When budgeting for a service crane in 2025, it’s essential to consider various cost factors that can significantly impact your investment. According to a recent industry report by MarketsandMarkets, the service crane market is projected to grow at a CAGR of 4.5% from 2023 to 2028, indicating a steady increase in demand. This growth suggests that prices may rise as manufacturers adapt to an expanding market and innovations in technology. Thus, planning your budget now can offer a competitive edge, allowing for timely purchases before potential price increases.

A crucial aspect of budgeting is understanding the total cost of ownership (TCO). This includes not just the initial purchase price but also operational costs such as maintenance, fuel, and insurance. For instance, the 2022 Cost of Maintenance Survey by the National Association of Equipment Dealers found that maintenance could account for approximately 30% of the total lifecycle cost of a crane.

Investing in higher-quality equipment might lead to lower maintenance costs over time, which is a vital consideration for budgeting. Additionally, incorporating technology such as telematics can provide real-time data on operational efficiency, potentially reducing unexpected costs and enhancing budget predictability.

Furthermore, financing options should also be evaluated. Many companies are opting for lease-to-own arrangements or financing solutions, which have seen an increase of 25% in utilization according to Equipment Leasing and Finance Association. These options can help spread the costs over time, making it easier to manage cash flow while ensuring access to the latest crane technology. Ultimately, a comprehensive understanding of these budget considerations is essential for making an informed decision on your service crane purchase in 2025.

Related Posts

-

Maximizing Efficiency: How Grove Cranes Are Shaping the Future of Construction with 20% Increased Productivity

-

What is a Construction Crane? Understanding Types, Functions, and Uses in Modern Building Projects

-

What is a Truck Crane and How Does it Work

-

Why Investing in Construction Cranes Boosts Project Efficiency and Reduces Costs

-

2025 Top 10 Ton Overhead Crane Features and Benefits You Need to Know

-

Top 10 Essential Tips for Choosing the Best US Crane Services