Top Types of US Crane Equipment for Heavy Lifting Solutions?

The demand for heavy lifting solutions in the US construction and industrial sectors continues to rise. According to a report by Grand View Research, the US crane market is expected to reach $22 billion by 2025. This growth reflects the increasing need for efficient lifting equipment in various projects. US crane operators rely on diverse types of cranes to manage these tasks effectively.

Understanding the top types of US crane equipment is essential for operational success. From mobile cranes to tower cranes, each type serves a specific purpose. Mobile cranes are versatile and can easily navigate job sites. Meanwhile, tower cranes are ideal for large construction projects. The right choice significantly impacts project efficiency and safety.

However, not all lifting solutions are perfect. Challenges exist, such as increased operational costs and maintenance issues. Operators must navigate these complexities to ensure seamless operations. Staying informed about equipment advancements and industry trends will remain vital for success in the evolving landscape of US crane usage.

Types of Crane Equipment Commonly Used in the US

When it comes to heavy lifting, cranes are essential. Several types are commonly used in the US. The mobile crane is versatile. It can move around the job site easily. This flexibility makes it a favorite for construction projects.

Another popular type is the tower crane. Tower cranes reach great heights. They deliver heavy materials to high locations. Their stability is crucial for skyscraper construction. Many workers rely on them for safety and efficiency.

Tips: Always assess the site before choosing a crane type. Factors like terrain and weight capacity matter. Don't rush the decision. Selecting the wrong crane can lead to accidents.

The overhead crane is also significant in warehouses. It provides excellent lifting capabilities in tight spaces. However, users must be trained to operate them effectively. Training mistakes can cause serious issues. Always prioritize safety and proper operation.

Hydraulic Cranes: Mechanisms and Applications for Heavy Lifting

Hydraulic cranes are essential tools in heavy lifting. They utilize hydraulic systems to lift and move massive loads. The mechanism relies on fluid pressure to generate lifting power. This design allows for smooth operation, even under heavy stress. It’s fascinating how a small amount of hydraulic fluid can lift tons of weight. Yet, it's not without challenges.

Applications of hydraulic cranes are vast. They are commonly used on construction sites, in warehouses, and for transportation. The ability to maneuver in tight spaces makes them invaluable. However, operators must be trained properly. Miscalculations can lead to accidents. Even experienced operators can face unexpected issues. Regular maintenance is crucial to avoid failures during critical lifts.

Understanding the limitations of hydraulic cranes is necessary. Weight capacities can vary significantly based on design. Not every crane can handle every job. It's essential to select the right equipment for specific needs. This decision can make all the difference in safety and efficiency. Balancing power and precision is key in hydraulic crane operations.

Crawler Cranes: Advantages and Limitations in Construction Sites

Crawler cranes are essential for heavy lifting in construction. They are designed to travel over rough terrain. Their wide tracks provide stability, allowing them to handle significant loads. However, their mobility can be limited on soft ground or steep slopes. Operators must account for these factors when planning a lift.

These machines excel in situations where space is restricted. They can maneuver in tight areas that larger cranes cannot access. Crawler cranes can also be disassembled for transport. This feature is advantageous for projects in remote locations. Yet, the setup process can be time-consuming and complex. Proper planning is crucial to avoid unnecessary delays.

Despite their strengths, crawler cranes have limitations. They are not as fast as some other crane types. Quick lifting operations may suffer due to this slower pace. Additionally, weather conditions can pose challenges. High winds can affect their stability and lifting capacity. Understanding these aspects is vital for effective project management.

Rough Terrain Cranes: Design Features for Off-Road Operations

Rough terrain cranes are designed specifically for off-road operations. They are perfect for construction sites with uneven surfaces. These cranes can tackle challenging landscapes where traditional cranes might struggle. High ground clearance is a key feature. It allows better mobility over obstacles.

Their wide stance enhances stability, which is crucial when lifting heavy loads. Equipped with robust tires, they navigate through mud and rocks with ease. However, operators need to be cautious. The weight distribution can shift quickly. Training is essential to handle these machines properly.

The flexibility of rough terrain cranes is impressive. They can extend their booms to reach elevated points. This feature is vital for tall structures or difficult locations. Yet, understanding limits is critical. Overreaching can lead to dangerous situations. Operators must always assess conditions before engaging in heavy lifting tasks.

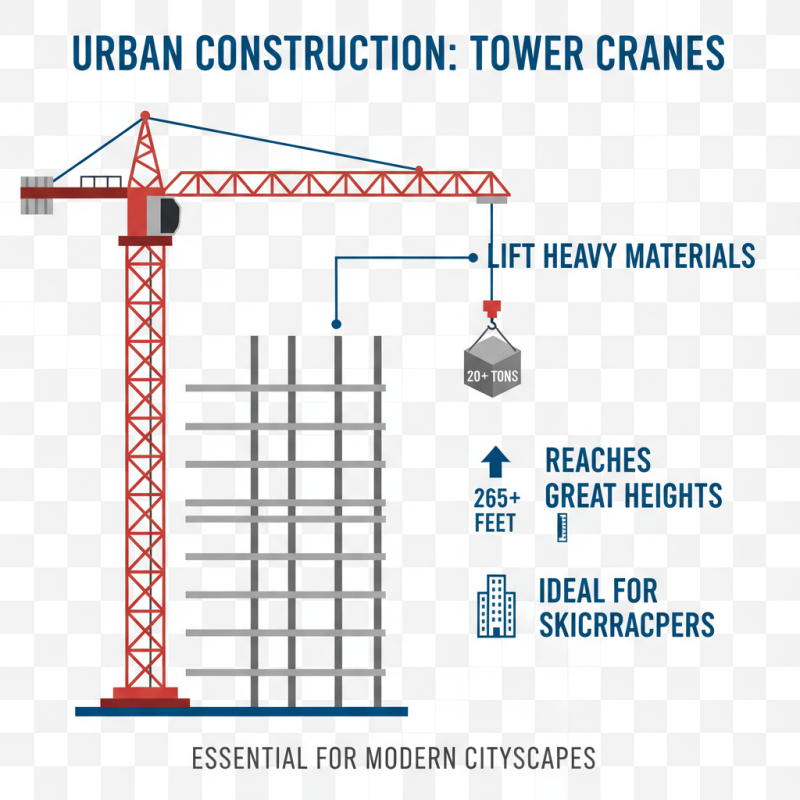

Tower Cranes: Key Characteristics for Urban Construction Projects

Tower cranes play a crucial role in urban construction projects. They lift heavy materials high above the ground, a necessity in densely built environments. A typical tower crane can reach heights of up to 265 feet and can lift loads exceeding 20 tons. This makes them ideal for skyscrapers and large commercial buildings.

The stability of tower cranes is vital. They are anchored to the ground and use a counterweight system to balance heavy loads. According to the National Commission for the Certification of Crane Operators, nearly 30% of crane accidents are due to tipping. This emphasizes the need for proper installation and operation. Workers must be well-trained to ensure safety.

Urban areas present unique challenges. Space is often limited, making it hard to maneuver heavy equipment. Tower cranes need to be meticulously planned into the project layout. In recent studies, 52% of construction leaders have reported delays due to crane-related issues. This highlights the importance of choosing the right crane type for the job and proper scheduling to minimize risks.

Related Posts

-

Maximizing Efficiency: How Grove Cranes Are Shaping the Future of Construction with 20% Increased Productivity

-

What is a Truck Crane and How Does it Work

-

How to Choose the Right Industrial Crane for Your Construction Projects

-

How to Identify and Observe Northern Cranes in Their Natural Habitat

-

What is a Central Crane and How Does it Improve Construction Efficiency

-

2025 Top 10 Ton Overhead Crane Features and Benefits You Need to Know